Steven DenBaars, a research scientist at UC Santa Barbara, has been working on LED lights for 20 years. He has been instrumental in pushing them to the point that they are the true heir to Edison’s electric bulb. But in his own head, and in his lab, DenBaars is already onto the next big thing: Replacing a substantial portion of indoor lights, and the archaic bulb and socket infrastructure on which they depend, with lasers.

If the thought of illuminating an office, airport or even your home with lasers conjures up images of rock concerts, dance clubs or 80’s-era superweapons, fear not: The results could be much more accessible, even naturalistic. And some experts say we could get there within 10 years.

Imagine, for example, the entire ceiling of a room lit up as if it were one big skylight. Or picture hotel ballrooms in which dozens or hundreds of bulbs are replaced by just a handful of ultra-bright light sources. DenBaars has—and now he’s just waiting for lighting designers to catch up.

How lasers could replace incandescent lightbulbs

At first blush it seems like there’s nothing in common between the warm glow of an incandescent lightbulb, which creates light by heating a filament until it’s white-hot, and a laser, which generates light in a single wavelength and shoots a focused beam at a a minuscule target.

The common ground is LED technology—it turns out that the kind of lasers DenBaars is working on are based on existing light emitting diodes, and are called “laser diodes.”

“It’s very similar to an LED lightbulb,” says DenBaars. “It’s the same materials, but you put two mirrors on either side of the LED and it breaks into a laser. Once you get reflection back and forth, you get an amplification effect, and it goes from regular emission to stimulated emission—it’s like an avalanche.”

The best laser diodes are about as effective at turning electricity into light as a store-bought LED, but with one major difference: You can pump more than 2,000 times as much electricity into a laser diode. In theory, that means per square centimeter, a laser diode can produce 2,000 times as much light.

Simply replacing the light emitting diodes in a typical LED bulb with a laser diode wouldn’t work. For one, this hypothetical laser lightbulb would catch on fire from all the waste heat it would generate. Also, it would produce an ungodly amount of light, more than enough to blind anyone who looked at it. (Imagine a sphere made out of lasers shooting in every direction at once, like some kind of sci-fi weapon.)

Rather, DenBaars imagines using just a handful of tiny but powerful lasers, and then redirecting their light into fiber optic cables and other types of light-transmitting plastic that could take that light and evenly distribute it into a warm, diffuse glow.

It’s like Amazon Kindle Paperwhite, but it’s your whole ceiling

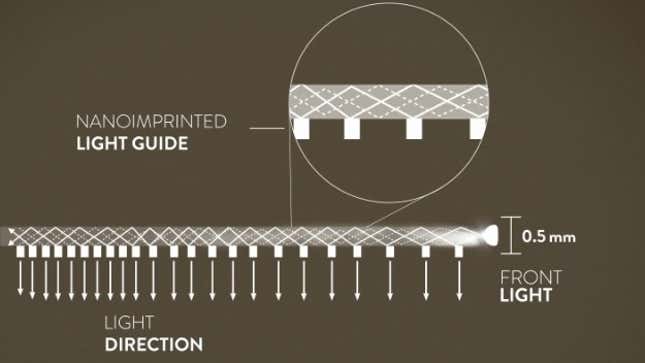

One way to evenly distribute laser light would be through what’s known as a waveguide. Waveguides are what allow the even illumination of the entire surface of Amazon’s Paperwhite display (not to mention other cutting-edge displays Amazon might be working on).

In this way, it would be possible to take a single point source of light and use it to create a diffuse glow that seems to be emanating directly from the materials of a ceiling—or wall, or floor, or light fixture of any conceivable shape.

“What you do is put that extra bright light source in a glass fiber, and you just weave it back and forth into squares, and scatter it over the ceiling,” says DenBaars. “It could even be cheap plastic fiber.”

BMW is already rolling out laser-based headlights

Lest you think this is a pipe dream, DenBaars points to at least one real-world example of laser-based lighting technology that’s about to be available to the general public: the headlights of BMW’s “hybrid supercar,” the i8. Using blue laser diodes, BMW’s engineers were able to create a focused (but not too focused) beam of white light. Like all lasers re-appropriated for conventional illumination, these are aimed at a phosphor that transforms the blue laser light into more diffuse white light. The result is headlights with such a long working life that they could “easily outlive the automobile” in which they’re installed, notes IEEE Spectrum.

Other forthcoming applications for laser illumination include IMAX movie theater projectors, televisions and computer monitors, head-mounted displays like Google Glass, and miniaturized “pico” projectors.

Lighting technology is moving so fast that lighting designers have yet to catch up

Even existing LED lights have reached only a fraction of their potential, says DenBaars, on account of limited imagination on the part of lighting designers. Because LED lights—and potentially laser-powered lights—are essentially flat, and can be bent into any shape imaginable, the possibilities for getting beyond the old model of one socket, one bulb are nearly limitless.

The problem is all nearly all buildings on earth that have electricity also have conventional lightbulb sockets. That’s why the first LED light most people will own will be shaped like a bulb, even though squeezing essentially flat LED lights into a round shape is absurd and leads to problems like overheating.

But laser lights could solve the problem of how to bridge the gap between traditional light sockets and more radical configurations of new lighting technologies. That’s because with just a few point sources of laser light installed in a building, their illumination can be redirected throughout a structure via plastic fiber optic cables that could be run along ceilings and around corners, just as the cable company runs its wires into buildings and through rooms without having to tear holes in walls or interface with the electrical system of a building.

It’s potentially easier, in other words, to pipe light from one place to another in a building than to re-configure its electrical wiring.

“Once you can put a light source into glass or plastic fiber, it frees you from having to put a light fixture every 20 feet,” says DenBaars. “Rather than route the electricity to the bulb you can route the light to the sources. LEDs let you do that too, but lasers would take it a couple steps further.”

DenBaars points out that it would even be possible to channel light through “free space,” without any fiber optic cables at all. That is, a central laser light source could shoot across the ceiling or down a hallway, into some kind of glass or plastic waveguide, and from there it would illuminate an entire room. It’s a weird concept, but when you eliminate the light bulb, you end up with ideas that Thomas Edison never even dreamed of.