There are many rites of passage that come in the wake of a new Apple product launch. There’s the analysis, the analysis of analysis, the reviews, the unboxings, and the endless takes—both hot and cold.

Another Apple product certainty: the teardown. Once a new product launches, some enterprising person or company will break down the components used to make the device, and assess how much each piece costs Apple to make.

Now, that has happened for the Apple Watch (its cheapest model, at least) and the results are fairly interesting.

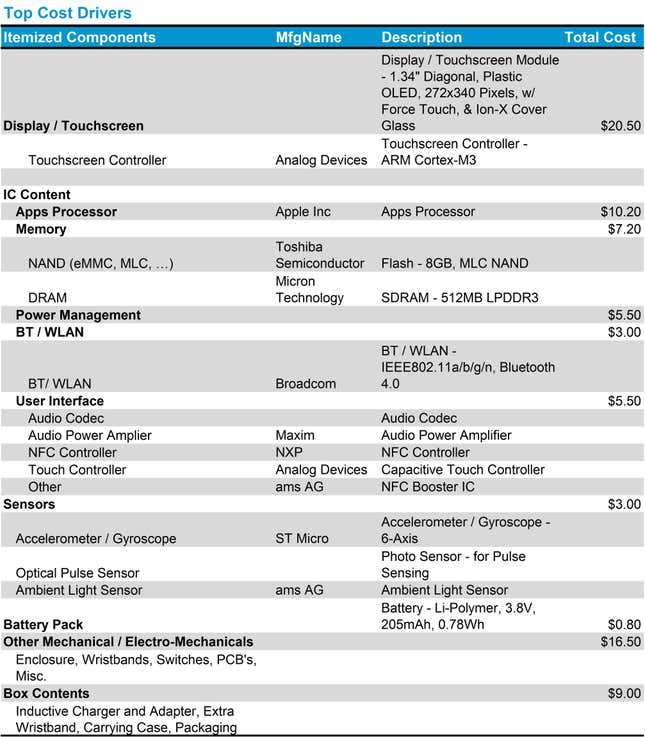

According to IHS Technology, the 38mm Apple Watch Sport, which sells for $350 in retail, costs Apple $83.70 to make and manufacture. Typically, manufacturing costs for Apple products are 29 to 38% of their suggested retail price, but, if IHS’s calculations are indeed accurate, the Apple Watch sport costs Apple only 24% of its retail price to build.

“The ratio for the Apple Watch is lower than what we saw for the iPhone 6 Plus and other new Apple products, and could be of great benefit to Apple’s bottom line if sales match the interest the Apple Watch has generated,” said Kevin Keller, a senior analyst for IHS, in a press release.

But Apple CEO Tim Cook disputes that IHS’s numbers are correct. ”Generally, there’s cost breakdowns that come out around our products that are much different than the reality,” he said this week on the company’s Q2 earnings call. “I’ve never seen one that is anywhere close to being accurate.”

Statements on that same earnings call by Apple CFO Luca Maestri seem to contradict the IHS breakdown as well. He said that Apple Watch margins are actually expected to be lower than the company average. Quartz has reached out to Apple for further comment on IHS Technology’s analysis, and will update this post with any response.

Of course, material and manufacturing costs don’t tell the whole story. Apple also has to pay for marketing, research and development, distribution, and untold other costs that ultimately factor into a product’s profit margin. So just because the Apple Watch Sport might seem cheap to make, that doesn’t necessarily translate to a massive return on profits.

Here’s the full breakdown from IHS. The device’s touchscreen display is the most expensive component, coming in at $20.50. The lithium polymer battery is the cheapest, at $0.80:

Image of the Apple Watch components is courtesy of iFixit.