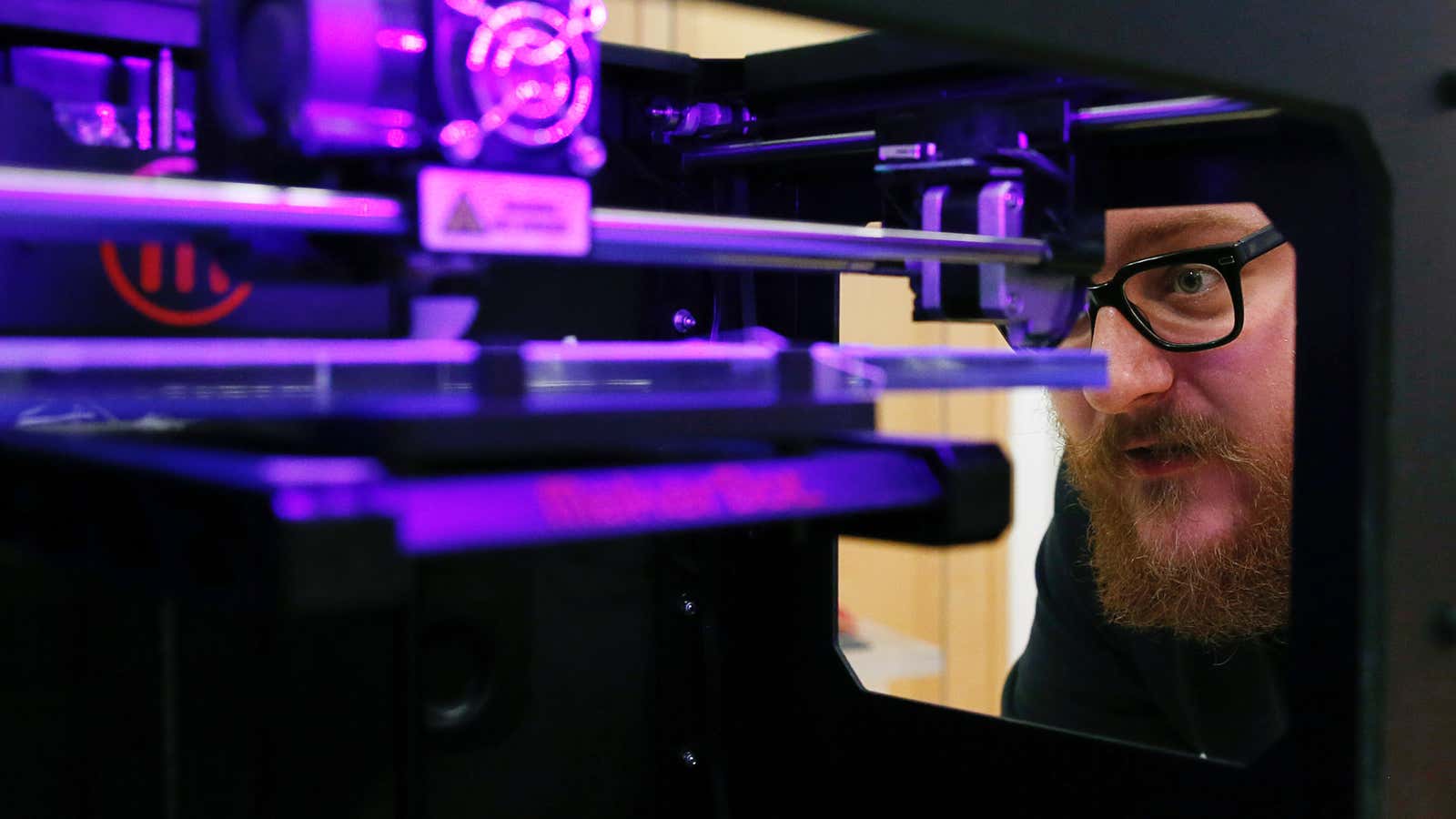

It’s been a rough year for MakerBot, and the dream of 3D printing your shoes, dinner, or electronics at home.

Today, the company once touted as a potential ”Apple” of the 3D printing industry, announced it’s going to stop producing its own printers. CEO Jonathan Jaglom said in a release that the company will be parting with an undisclosed number of its employees at its Brooklyn-based factory, and, according to the Verge, it will shut down the factory entirely.

In the last year, MakerBot has laid off 20% percent of its staff—twice—and closed all of its brick-and-mortar stores. It’s now adding the departure of its manufacturing staff to that list of leavers. Although MarkerBot wouldn’t say how many workers are departing, a spokesperson told Quartz that a “ significant number” factory workers will be affected.

MakerBot told Quartz that the remaining staff—its marketing, logistics, design, repair departments, and so on—will remain in Brooklyn. But its printers and other hardware will now be manufactured by Jabil Circuit, a US manufacturer for startups and electronics companies with factories across the world.

When Quartz spoke to Jaglom last year after the first round of layoffs, he said the company was refocusing efforts away from the consumer market of hobbyists and tinkerers, to science and technology programs at schools and universities. MakerBot confirmed that this is still the long-term goal, selling its desktop printers as prototyping machines to the design departments of companies, and to engineering schools.

MakerBot was acquired by Stratasys, a large industrial 3D printing company, in 2013. It installed the son of Stratasys’ board of directors—Elchanan Jaglom—as MakerBot’s CEO, who has since aligned the company more closely with its parent company. After the initial hype in 2013 and 2014 around the potential of 3D printing, MakerBot scaled up its production capacity in 2015. 3D printers were seen as the printing equivalent of Apple iPhones, consumer-ready products with a robust app ecosystem and active community of hobbyists on its Thingiverse design repository.

But consumer adoption of 3D printers beyond the maker community has been slow. When MakerBot was sold to Stratasys, it was reported that the company had sold about 22,000 printers since it was founded in 2009—a representative told Quartz that MakerBot has now sold a total of about 100,000 units, which equates to about 26,000 printers a year. Not exactly Apple numbers. (MakerBot’s cheapest printer costs about $1,400.)

3D printing is slowly proving itself as a manufacturing tool useful to those outside the industrial design world. Stratasys unveiled a printer earlier this month that can print objects out of multiple materials and colors at once, hinting at a future where we could actually print anything we need. MakerBot says its layoffs today will help it better manage demand for its products, without having to pay for increasingly expensive real estate of its Brooklyn factory.

Still, it’s difficult to see a third round of layoffs in a year in a positive light.

Perhaps students in schools today using MakerBot printers will be more inclined to buy one when they graduate, but a MakerBot spokesperson said that the focus for the next 7-10 years will likely remain in education. The market for cheap 3D printers is flooded—at 2016’s Consumer Electronics Show in Las Vegas, there was a seemingly endless parade of printers at just about every price imaginable—and it doesn’t seem that MakerBot is able to compete on price.

“To achieve our long-term goals, we also need to be able to navigate the volatility of an emerging market,” Jaglom said in today’s release. Consumer 3D printing is still in its infancy. Given its pricing, if 3D printing does come to our homes, it probably won’t be via a MakerBot printer.