Small-scale production in the hands of consumers is sometimes touted as the future of 3D printing technology, but it’s probably not going to happen.

A post on Make Magazine’s blog by Nick Pinkston, a software engineer who works with computer-aided design (the software that allows you to design the objects to be printed in 3D) argues that the concept of distributed manufacturing—that is, putting the production of the stuff you buy into your own hands (or that of a local store) via a 3D printer—”doesn’t hold water.” Just look at 2D printing: “Does Amazon have a bunch of HPs printing off their books? No way—they have very specialized machines doing this, and the same is true for everything in engineering.”

As good as 3D printers get, Pinkston says, someone will always be in the wings ready to make a better, faster one that you can’t afford. Basically, he thinks, what you can do at home will never be fast, cheap, or high-quality enough to make a dent in the demand for large-scale production.

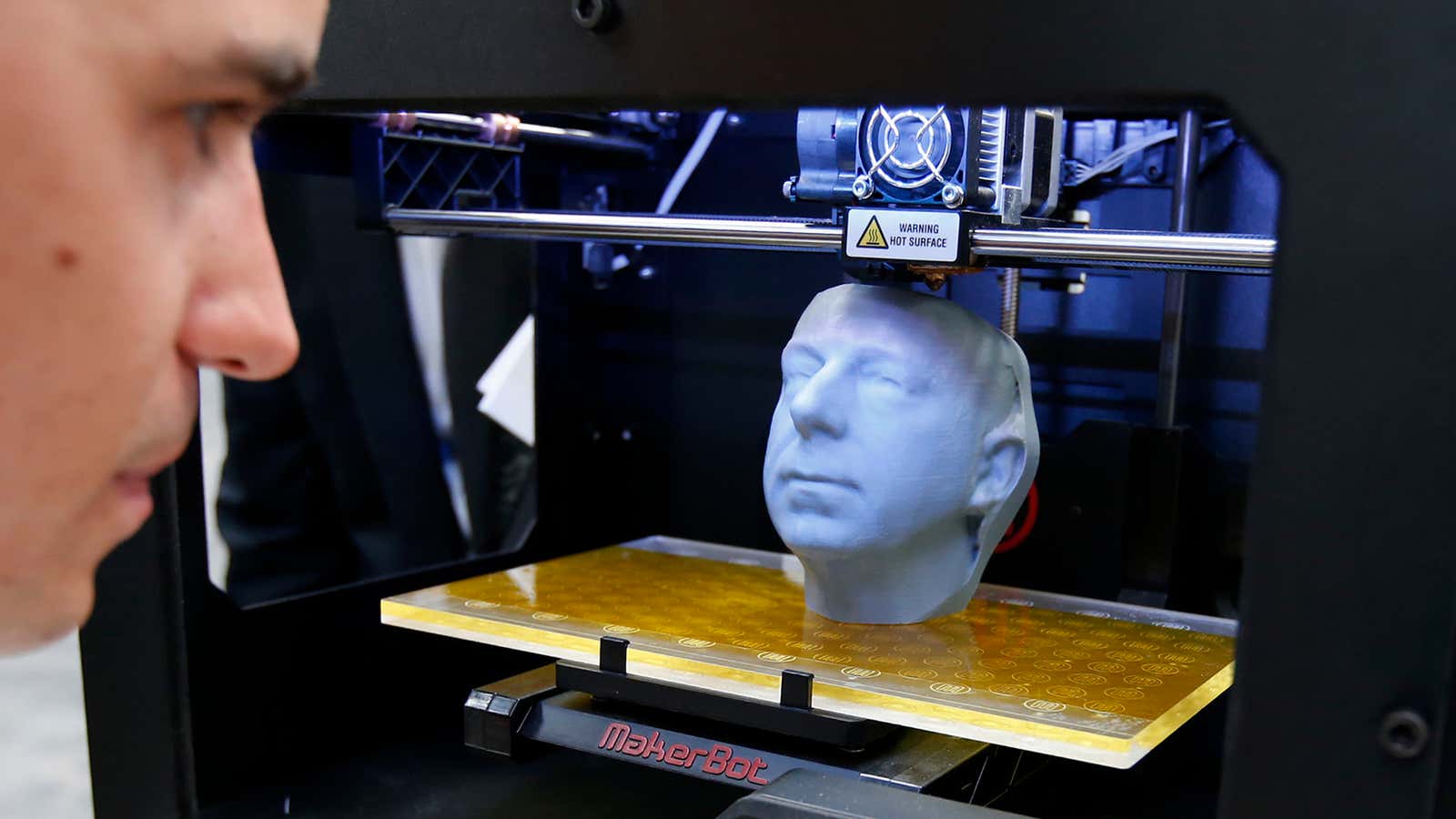

So what are they good for? 3D printers are ideal for prototyping, says Pinkston, and always will be: In making prototypes, speed and accessibility are more important than cost and quality. They may also be very useful if you need to make a very specific object that isn’t mass-produced. But when it comes time to manufacture a product, the 3D printer involved won’t be sitting on your desk.