MIT scientists created accessories that change color to match your outfit

Nearly everything we buy is fixed in one color. Whatever shade it’s made in, that’s how it stays, barring some labor-intensive painting or dyeing.

Nearly everything we buy is fixed in one color. Whatever shade it’s made in, that’s how it stays, barring some labor-intensive painting or dyeing.

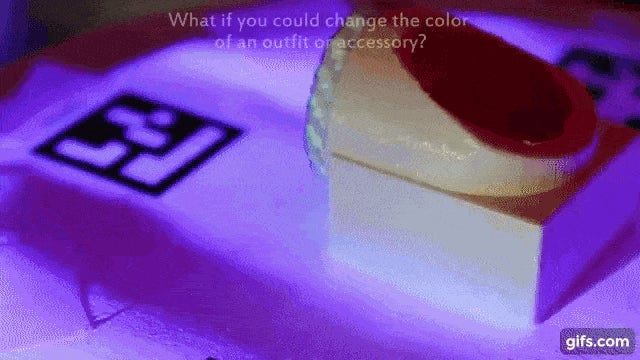

But a team of researchers at the Computer Science and Artificial Intelligence Lab (CSAIL) at MIT has devised a way to make objects that can toggle between different colors. You could make, say, a ring that you can switch from red to blue, quickly and easily—like a mood ring you’re in complete control of. While the researchers have only worked with 3D-printed plastic so far, they believe the concept could be applied to other items, including clothing. Imagine, for instance, a coat that could be changed to any one of a handful of preset colors, that you choose depending on your outfit.

The system, called ColorFab, works with photochromic inks that can be switched on and off between transparent and colored states when exposed to certain wavelengths of UV light. Using those inks, the researchers created a dense, multi-colored pattern of voxels—basically units of visual information, like pixels, only in 3D. They used a system of UV light and regular light projectors to activate and deactivate the voxels they wanted.

The colors remain visible after they’ve been activated, even out of the UV light, and sunlight won’t activate or deactivate them, so there’s no need to worry about your accessories changing color the moment you walk out the front door. The colors do fade after several weeks, however, and need to be reactivated.

The team started with 3D printing because “painting such a dense multi-color pattern onto the object’s surface by hand is not feasible,” it said in its research paper (pdf), which includes details on how others can 3D print with photochromic inks. (The paper hasn’t been peer-reviewed yet, but has been accepted for presentation at this year’s ACM CHI Conference on Human Factors in Computing Systems).

Theoretically, the concept should work on any surface that can be printed with the pattern of photochromic voxels.

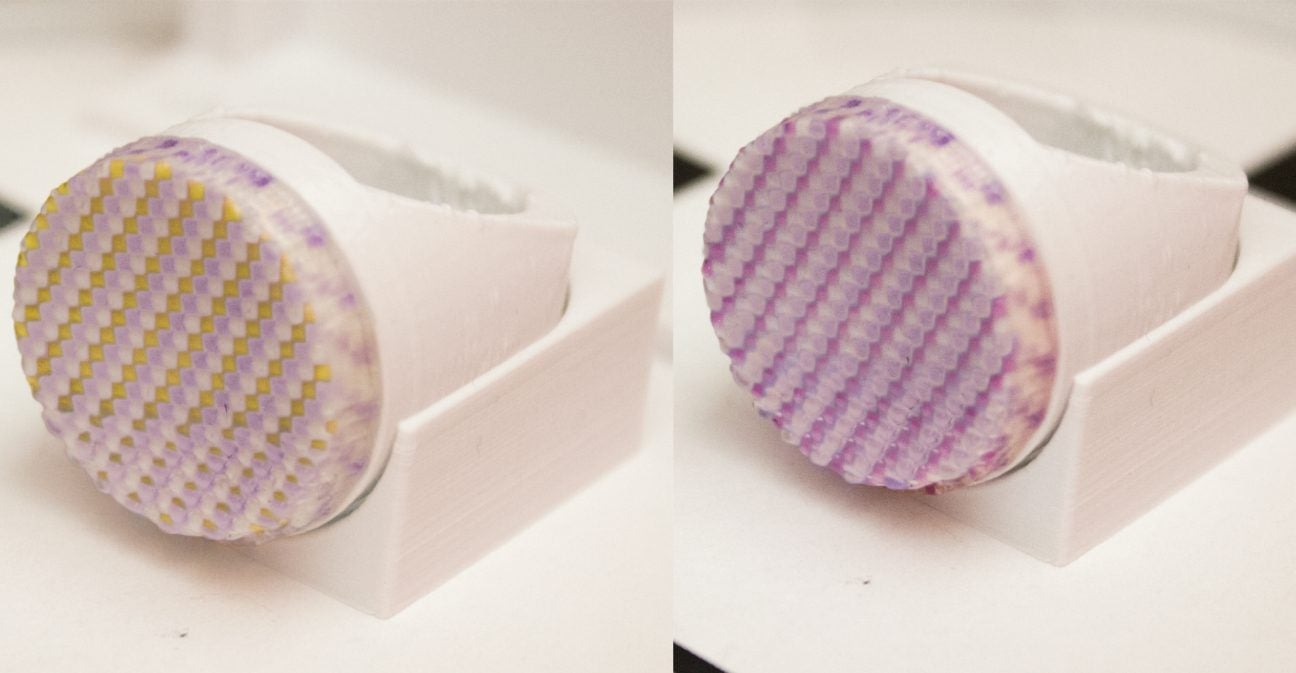

The MIT team says that because their 3D printer did not have a very high resolution, the colors on their proof-of-concept examples don’t look saturated, and you can easily see the multi-colored pattern. “One of our goals is to improve the granularity of the printing,” says Stefanie Mueller, the CSAIL professor who led the development of ColorFab. In its paper, the team writes that “future advances in hardware will likely raise the resolution by several orders of magnitude.” As resolution increases, the pattern will cease to look like a multi-colored grid and will look more and more to the eye like a solid field of color.

The team is working to improve the process in other ways as well. Right now it takes about 23 minutes of UV exposure for an object to change color. That could be sped up, they say, with a more powerful light, or using more light-sensitive dye in the ink.

Eventually they believe this technology could one day let people quickly match accessories to outfits, or let retail stores switch the color of clothing or other items on the spot for customers. The team’s long-term goal, it says, “is to allow users to recolor objects while on the go using a smart phone with an integrated micro-projector and UV light.” There’s a way to go before we’re at that point, but for anyone who might get twice as much use out of a purchase if it could change color, it’s an intriguing idea.