How Tesla “shot itself in the foot” by trying to hyper-automate its factory

In a more automated future, it’s still vital to appreciate what humans can do better.

Investors and fans of Tesla are anxious to hear what the company has to say about the production ramp of the Model 3, the main driver of future profits and cash-flow, when it releases its first-quarter results on May 2.

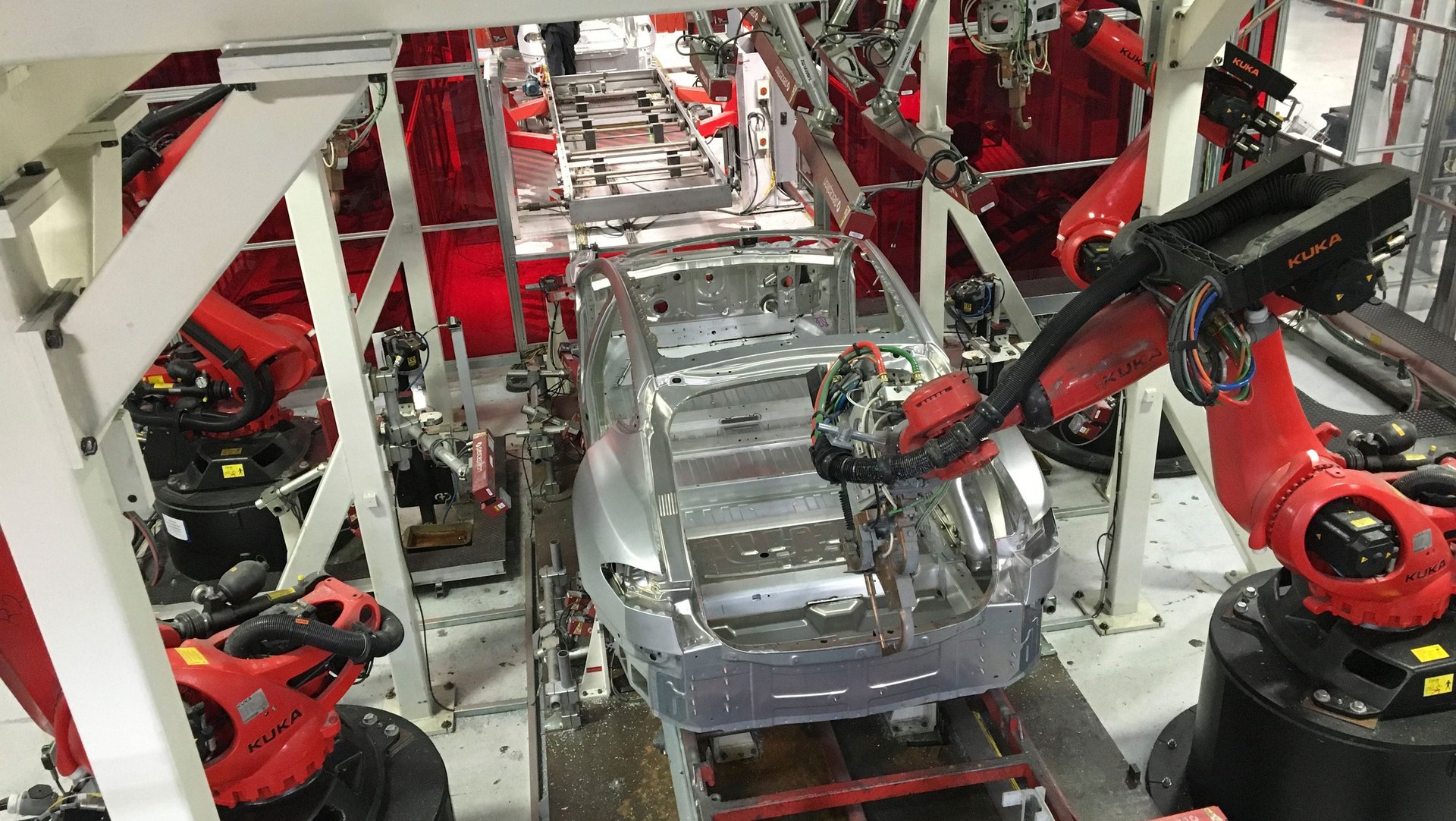

Analysts at Bernstein and UBS recently released reports that focus specifically on the problems with “over-automation” of the Model 3 line, production of which is now approximately 2,000 vehicles per week—nowhere near the company’s target of 5,000 vehicles per week.

Founder and CEO Elon Musk, for years one of strongest proponents of a future where there are no people in the production process and his factory looks like an alien spaceship, is now acknowledging that the optimal level of automation remains a complex balancing act of design, productivity, quality, and human and machine skills.

He recently blamed an overly automated production process as the reason for missing Tesla’s output targets. “Humans are underrated,” he tweeted. And Musk added to CBS, “We had this crazy, complex network of conveyor belts… and it was not working, so we got rid of that whole thing.”

In the Bernstein analysis, Toni Sacconaghi and Max Warburton offer some explanation as to why it’s proving so difficult to ramp up production on an overly automated line. Warburton’s background includes time spent benchmarking vehicle-assembly plants and he states that, in attempting to hyper-automate Model 3 production at its Fremont plant in California, Tesla “may have shot itself in the foot.”

“Automation simply can’t deal with the complexity, inconsistencies, variation and ‘things gone wrong’ that humans can,” and “can create quality problems further down the line,” they say. The Bernstein analysts deduce that Tesla’s troubles are because of the complexity of automating final assembly, where the car is put together. This is something that’s been tried before by other manufacturers—such as Fiat, Volkswagen, and GM—and they have all failed. Sacconaghi and Warburton say:

In final assembly, robots can apply torque consistently—but they don’t detect and account for threads that aren’t straight, bolts that don’t quite fit, fasteners that don’t align or seals that have a defect. Humans are really good at this. Have you wondered why Teslas have wind-noise problems, squeaks and rattles, and bits of trim that fall off? Now you have your answer.

The Bernstein analysts point out that final assembly is fundamentally an exercise in flexibility because the process is constrained by the ability to feed the right part at the right time. Humans are able to spot things that aren’t right, stop the process, and try to get them fixed. One of the important ways that simple design contributes to simpler final assembly is in how many parts and how much space is required alongside the assembly line. Robots aren’t as flexible as humans; they aren’t as good as humans at adapting to product variants nor can they handle as many complex movements as humans.

This means that, beyond a certain point, automation can raise costs, and contrary to what you’d expect, not help quality or productivity. Importantly, automation needs to be overlaid on a stable process to ensure that it’s not the errors that are being automated. This will be especially important once machines are learning on their own, because there’s not necessarily a human to notice if an error is being propagated.

As we enter an age of machines that can learn directly from data rather than being programmed by humans, Tesla’s experience with a hyper-automated production process is important to understand. In a more automated future, it’s still vital to appreciate what humans can do better.