Ford is using airbag material to make reusable hospital gowns for Covid-19 responders

Battling Covid-19 requires an elaborate armor. First responders don masks, shields, respirators, and other personal protective equipment to protect themselves from the fast-spreading airborne virus.

Battling Covid-19 requires an elaborate armor. First responders don masks, shields, respirators, and other personal protective equipment to protect themselves from the fast-spreading airborne virus.

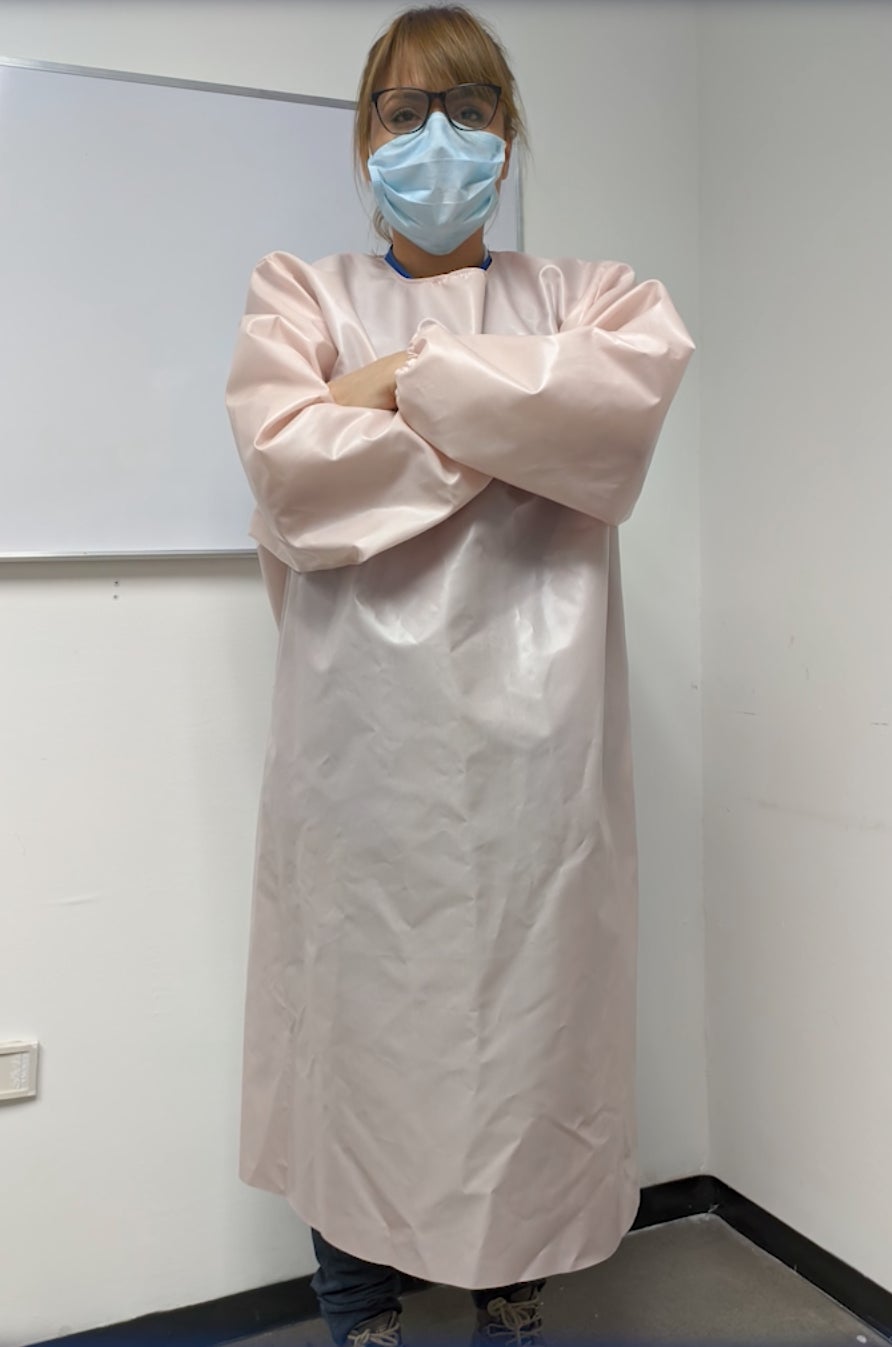

A staple protective gear is the isolation gown. Made from waterproof material and typically designed with long sleeves and snap closures, they protect health care workers while treating patients from splashes and sprays. According to a 2015 survey by the US National Health Institute, isolation gowns are the second-most used piece of PPE after medical gloves. Amid the coronavirus pandemic, these gowns are in such short supply that the US Centers for Disease Control (CDC) has recently recommended tactics to extend the use of the typically single-use coverings.

Responding to the shortage, automaker Ford has started producing hospital-grade isolation gowns with the fabric used in its airbags. Made of a sturdy, water-resistant nylon with a silicon coating, the gowns can be laundered and reused up to 50 times. At an April 13 press briefing, the Michigan-based company revealed that it plans to work with Joyson Safety Systems, its airbag supplier, to manufacture 100,000 gowns each week with a goal of delivering 1.3 million units by early July.

Reusing hospital gowns isn’t always easy, as the CDC’s memo outlines. Flimsy disposable gowns are prone to ripping and would require special sanitation processes to be safely reused.

It turns out, the Nylon 6,6 material used in vehicle airbags as well as parachutes, carpets, and garden hoses makes for an ideal PPE material. “This was a really great find,” explains Ford director Marcy Fisher at the briefing, noting how the lightweight fabric is perfectly fluid-resistant. “The gowns are washable and they retained their performance qualities… after 50 times in the wash.”

Ford, which consulted a local hospital to finesse the sewing pattern for the isolation gowns, told Quartz that it conducted internal tests to make sure they’re meeting the standards set by the American Society for Testing and Materials (ASTM F3352-19) and the Association for the Advancement of Medical Instrumentation (ANSI-AAMI PB70-2012).

Ford’s rapid gown-making program is part of its Covid-19 response partnership with 3M, GE, and a range of manufacturing partners. Last month, it announced plans to mine its supply chain for stock car parts that can be used to augment the design and production of medical equipment during the pandemic.

With most big car companies having halted production, Ford is one of several automakers that has re-deployed its resources to fight the pandemic. Companies like General Motors and Tesla have transformed several of their factories into ventilator and face mask production plants.