How a pump, sensor, and meter will change the way we recover oil and gas

This article is part of an ongoing BULLETIN series exploring GE’s innovation, technology, and manufacturing initiatives in India.

This article is part of an ongoing BULLETIN series exploring GE’s innovation, technology, and manufacturing initiatives in India.

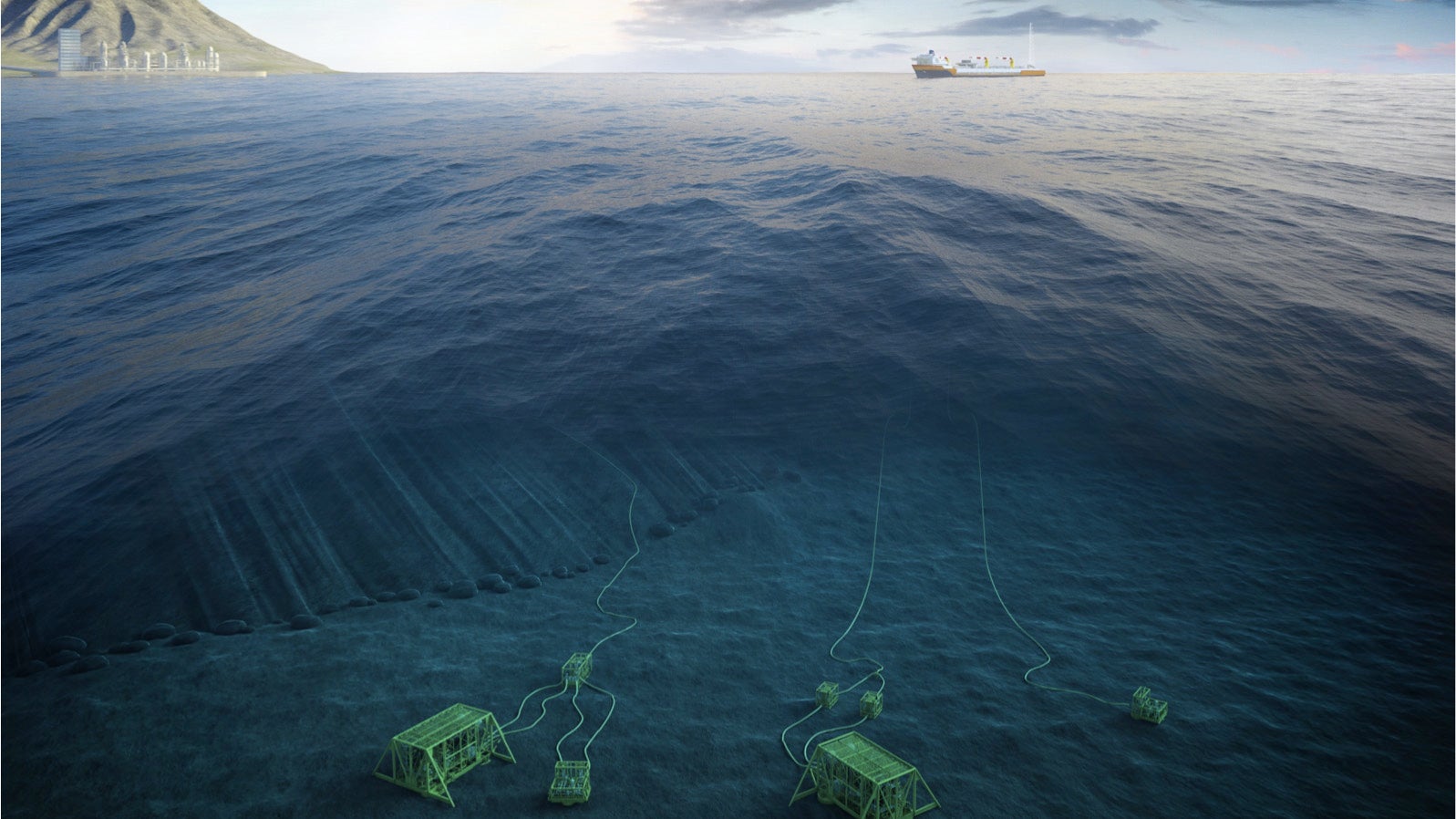

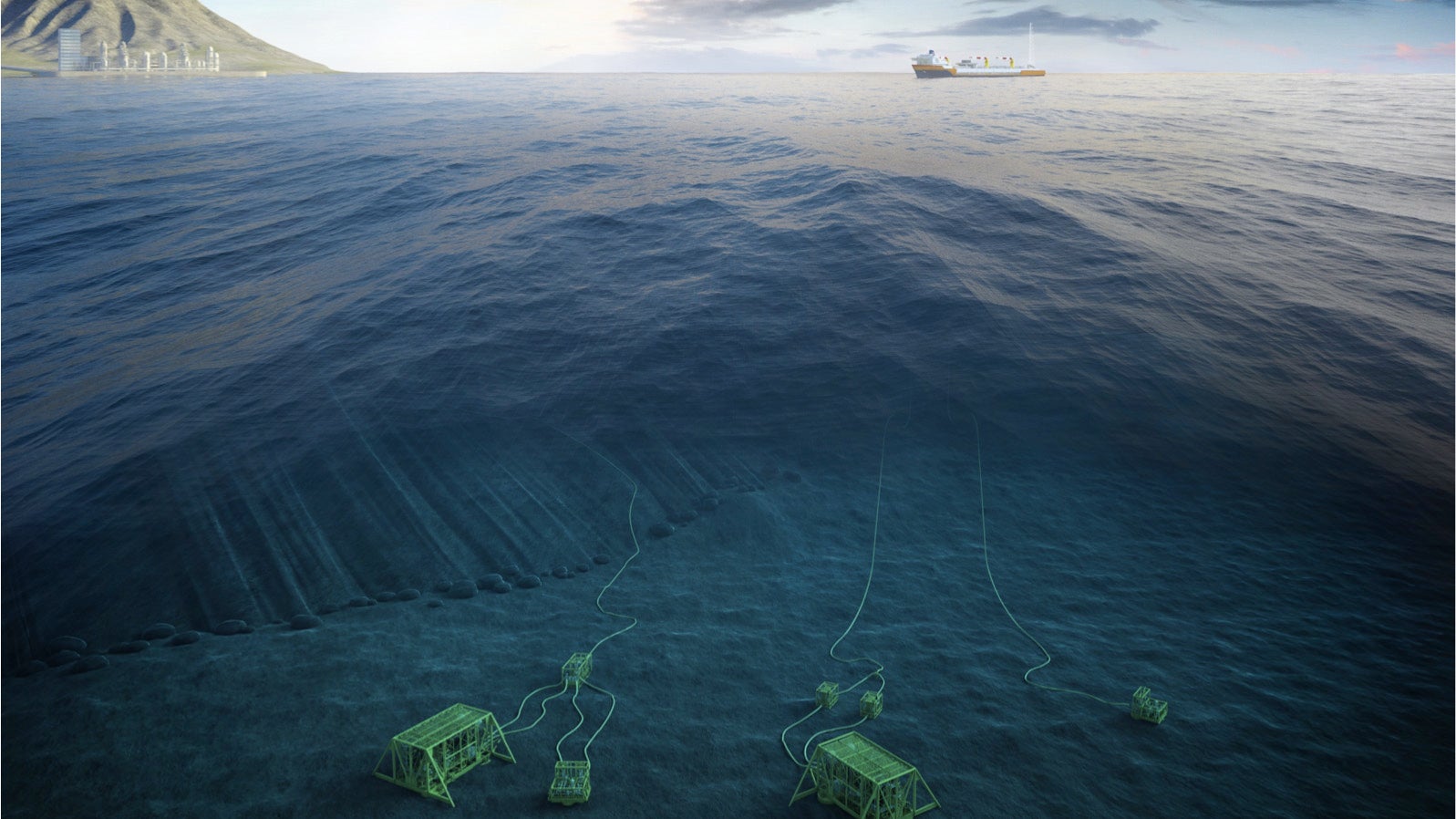

In Munich, a multidisciplinary team of GE researchers is enabling a subsea plant that can process oil and gas right on the seabed floor, at depths of 3,000 meters and more than 100 kilometers offshore. In Shanghai, GE’s High Power Electronics team is developing new technologies that will enable electronics used in oil and gas production to function reliably at deeper depths and higher pressures. In Rio de Janeiro, GE is working with local customers to develop new sensing, drilling, and production technologies to recover new subsea oil and gas reserves that exist underneath a layer of salt off the coast of Brazil. Efforts like these aim to push the boundaries of oil and gas production and solve some of the industry’s toughest challenges.

GE’s oil and gas technologists are also advancing products that address specific needs and enhance recovery. A team of researchers in Bangalore, along with GE Oil and Gas teams in Boston, USA and Groby, UK, is developing a multiphase flow meter technology to enable more accurate measurement of a mixture of liquids–such as oil and water–in harsh environments. At GE’s global research headquarters in Niskayuna, New York, pump technology is being developed to gain access to “unconventional” wells and advanced sensors are making it possible to operate in high-temperature and high-pressure locations. We look at these three innovations in greater detail below.

Multiphase flow meter

The importance of the quantitative and qualitative analysis of fluid flow in the oil and gas exploration industry cannot be overstated. Yet, currently, most devices can only be used for monthly or weekly measurements. Even small changes in the composition of the fluid can adversely impact a flow meter’s ability to function and accurately gather data. The uncertainties associated with these measurements have led to industry skepticism about the accuracy of the meter readings.

GE’s multiphase flow meter updates whenever there is a change in fluid properties, eliminating the need for frequent fluid sampling. Most flow meters cannot operate seamlessly if the fluid changes from an “oil suspended in water phase” to a “water suspended in oil phase” and vice versa. GE’s Safire multiphase meter has the bandwidth to make measurements for both flow types.

The Safire’s measurement data can be obtained in real-time through a complex integration of machinery with networked sensors and customisable software–Industrial Internet tools–to analyse and store all data obtained from the flow meter. This sophisticated technology leads to one simple outcome: operators can optimise and maximise the cost-effectiveness of production. Thanks to GE’s “more data, more oil” philosophy, the Safire multiphase flow meter helps operators make even low-yield wells profitable sources of energy.

Electric submersible pumps

For nearly a century, pumps utilizing centrifugal force have helped bring hydrocarbons to the surface. Reaching average depths of nearly 2,000 meters, these electric submersible pumps (ESPs) can be thought of as straws that siphon tough-to-reach deposits out of the ground. Today, there are more than 130,000 ESPs installed globally, including installations at depleting reservoirs in Rajasthan, Assam, and the Bombay High offshore basin. All of those ESPs account for more than 60% of global oil production.

GE is taking the ESP to a new level by introducing technology that meets the demands of “unconventional” wells, where oil is mixed with water, gas, and sand. Conventional ESPs are challenged by that mixture, so GE has developed advanced coating technology that dramatically improves performance and resistance to wear and abrasion, providing the ability to reach reserves that, right now, go largely underutilized.

Smart sensing systems

Physicists in GE’s Photonics Laboratory are developing fiber optic sensors to measure temperature, pressure, and acoustic conditions in deep, harsh environments.

These sensors will ensure the collection of reliable data about an oil or gas field and improve the monitoring and productivity of the wells in which they are installed. Further, they’re packaged in a way that will allow them to operate for 20 years in waters up to 2 kilometers deep. This will ensure not only the collection of reliable data about oil fields, but expands the scope of types of information that can be captured.

All in all, these innovations are bent on tackling the immense challenge of operating outsized exploratory machinery cleanly and reliably in the extreme sub-depths of the sea. And that challenge is magnified when considering the rapidly expanding energy needs around the globe. In order to responsibly and sufficiently respond to future demand, the seabed oil and gas production process will have to be continually refined. These researchers, technologists, and physicists get that: together, their research is improving energy production in smarter, safer, and more efficient ways.

Click here

to answer a few questions about energy innovation in India.

This article was produced on behalf of GE by the Quartz marketing team and not by the Quartz editorial staff.