Your fancy zippers are forcing Chinese laborers into mind-numbing drudgery

Recently, a friend of mine named Akiba took me to visit his friend’s zipper factory in China. I love visiting factories: no matter how simple the product, I learn something new.

Recently, a friend of mine named Akiba took me to visit his friend’s zipper factory in China. I love visiting factories: no matter how simple the product, I learn something new.

This factory is a highly automated, vertically integrated manufacturer. To give you an idea of what that means, they take this:

and this:

and turn it into this:

In between the inputted material and the outputted product, however, is a fully automated die casting line. This line consists of a set of tumblers and vibrating pots that release and polish the zippers, along with a set of machines that de-burr and join the zipper’s puller to its slider. I think I counted less than a dozen employees in the facility and I’m guessing their capacity well exceeds a million zippers a month.

I find vibrapots mesmerizing. I actually don’t know if that’s what they are called — I just call them that. It looks as if the sliders and pullers are lining themselves up in the right orientation by magic, falling into a rail and being pressed together into that familiar zipper form, all in a single, fully automated machine.

Yet despite the high level of automation in this factory, many of the workers I saw were manually separating zippers from the rail. This begs the question: Why is it that some zippers have fully automated assembly processes, whereas others are semi-automatic?

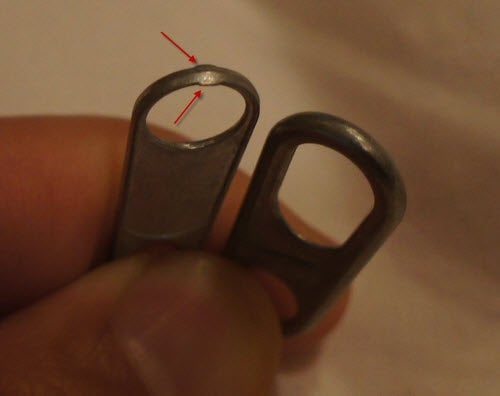

The answer, it turns out, is very subtle. When the pullers come around the rail, their orientation is random: some are facing right, some facing left. But the joining operation must only insert the slider into the smaller of the two holes. A tiny tab on the top of the zipper allows gravity to cause all the pullers to hang in the same direction as they fall into a rail on the left.

The semi-automated zipper design doesn’t have this tab; as a result, the design is too symmetric for a vibrapot to align the puller. Essentially, this tiny tab, barely visible, is the difference between full automation and a human having to join millions of sliders and pullers together. I asked the factory owner if adding the tiny tab would save this labor. His answer? Absolutely.

At this point, it seems blindingly obvious to me that all zippers should have this tiny tab, but the zipper’s designer wouldn’t have it. Even though the tab is very small, a user can feel the subtle bump and it’s perceived as a defect. As a result, the designer insists upon a perfectly smooth tab, therefore requiring manual orientation during production.

I’d like to imagine that most people, after watching a person join pullers to sliders for a couple of minutes, would be willing to suffer the tiny bump on the tip of their zipper in order to save another human the fate of having to manually align small pieces of metal for eight hours a day. I suppose alternately, an engineer could spend countless hours trying to design a more complex method for aligning the pullers and sliders. But the zipper’s customer probably wouldn’t pay for that effort and it’s probably net cheaper to pay unskilled labor to manually perform the sorting anyway. They’ve already automated everything else in this factory, so I figure they’ve thought long and hard about this problem, too. My guess is that robots are expensive to build and maintain while people are self-replicating and largely self-maintaining.

Of course, in reality it’s far too much effort to explain this to customers, and in fact quite the opposite happens in the market. Because of the extra labor involved in putting these zippers together, the zippers cost more and therefore tend to end up in higher-end products. This further enforces the notion that smooth zippers with no tiny tab on them must be the result of quality control and attention to detail.

My world is full of small frustrations like these. For example, most customers perceive plastics with a mirror-finish to be of a higher quality than those with a satin finish. While functionally there is no difference in the plastic’s structural performance, it takes a lot more effort to make something with a mirror-finish. For all that effort, for all that waste, what’s the first thing a user does? Put their dirty fingerprints all over the mirror finish. Within a minute of coming out of the box, all that effort is undone.