A 3D printing startup backed by Carmelo Anthony wants to banish shoe sizes

Trying on shoes is a hassle. After sifting through endless varieties to find a pair you like, they end up being a bit too tight or too loose, and the clerk invariably says it’s the only size they have; you leave disappointed. One startup is trying to change this—with a combination of 3D scanning and printing—by creating shoes and insoles that perfectly fit your feet, whatever size they may be.

Trying on shoes is a hassle. After sifting through endless varieties to find a pair you like, they end up being a bit too tight or too loose, and the clerk invariably says it’s the only size they have; you leave disappointed. One startup is trying to change this—with a combination of 3D scanning and printing—by creating shoes and insoles that perfectly fit your feet, whatever size they may be.

SOLS, a startup based in New York, spent the last year perfecting personalized 3D-printed corrective insoles, and now wants to start creating custom-built shoes as well. As founder Kegan Schouwenburg told Quartz, she wanted to create “software that enables us to take our physical world and digitize it” and then come full circle, creating a physical product “that’s perfect and unique for you.”

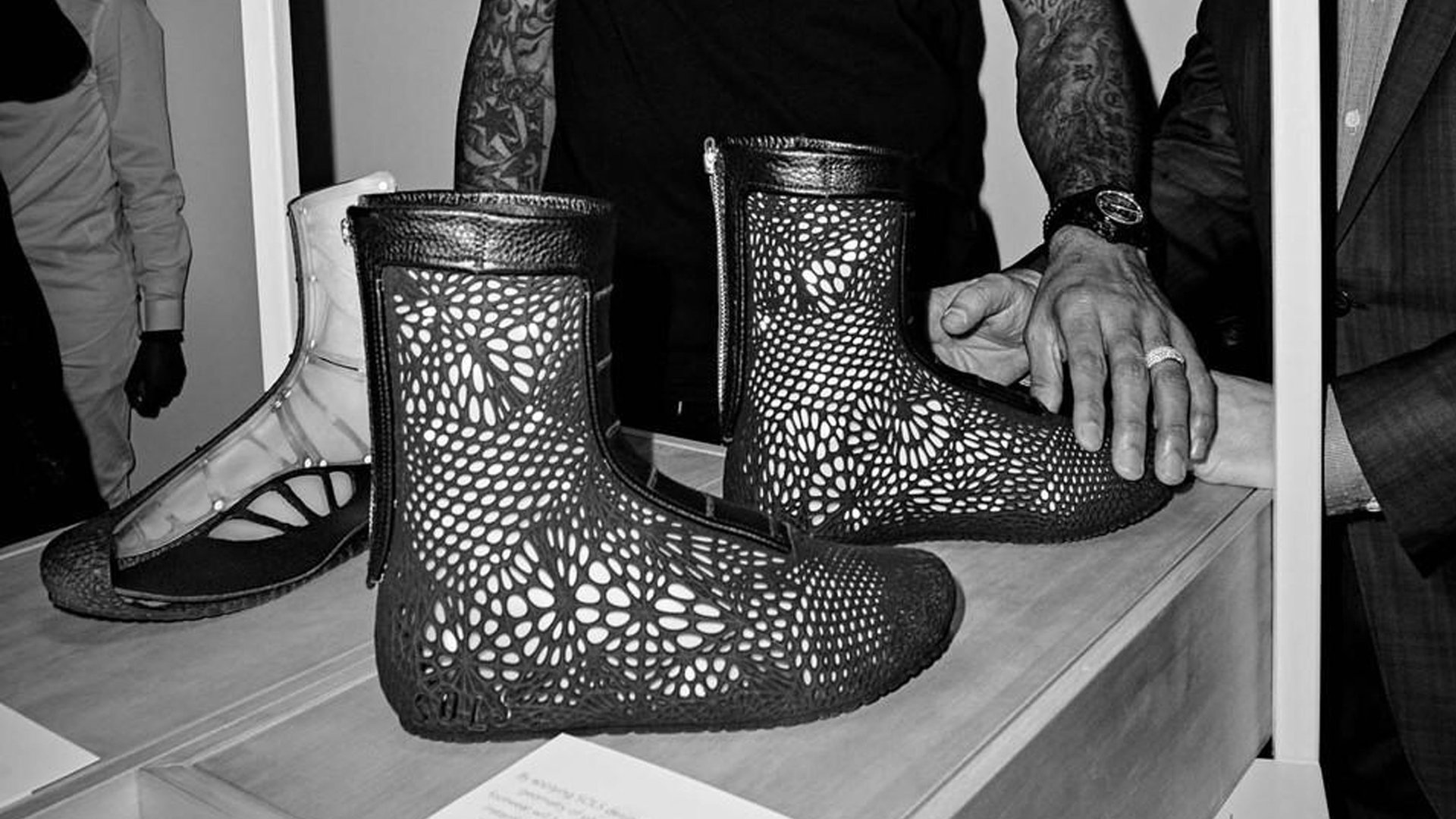

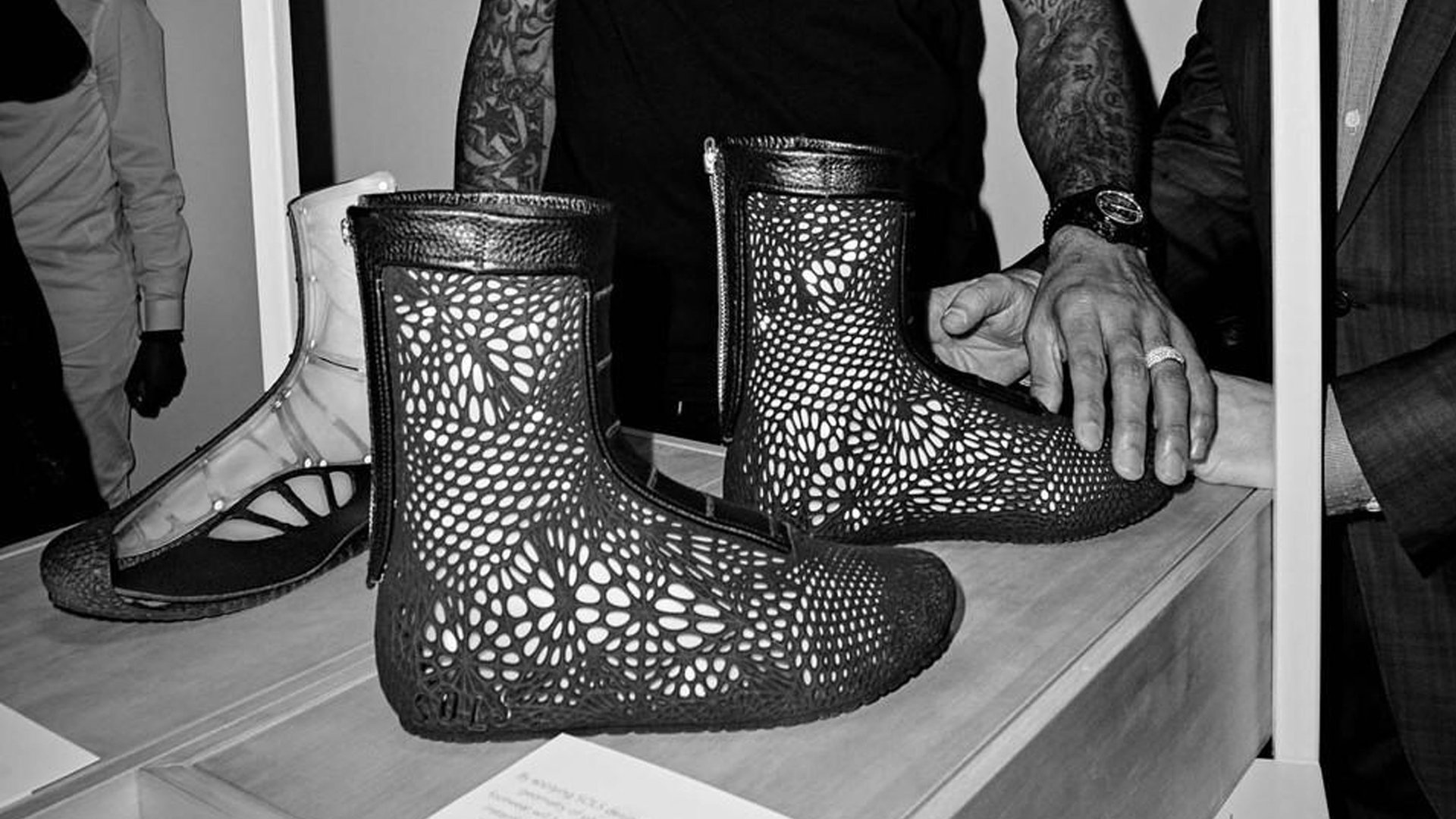

SOLS’ process involves taking photos of a foot from three different angles (which can be done using a regular smartphone), modeling them digitally, then printing insoles to match the exact topography. Schouwenburg said SOLS is now shipping hundreds of insoles each week, and the company recently unveiled Adaptiv, a 3D-printed prototype shoe that can be customized and finished in multiple materials.

Schouwenburg said 3D printing is just one technique as just part of the future of automated, personalized shoemaking. ”Most products are multiple materials,” she said. “3D printing will be part of the change, but it’ll be combined with things like injection molding, rapid casting, milling—that’s where things like on-demand modular footwear really become possible.”

The company announced today that is has secured a second round of funding realize its vision. The first round was partly funded by Melo7 Tech Partners, a group spearheaded by NBA star Carmelo Anthony. SOLS also announced a new board member—Terdema Ussery, the CEO of the NBA’s Dallas Mavericks, who previously spent time at Nike. Schouwenburg said that part of Ussery’s time will be spent working on making SOLS’ insoles and shoes more accessible to consumers.

SOLS is also working with EOS, a German 3D printing firm, to build a large-scale printing factory in Temple, Texas that will be able to produce up to 10,000 insoles a day. The goal is to be able to eventually use the factory to produce shoes, 3D printing them from orders sent via customer’s smartphones. The shoes would then be sent to a network of studios to be finished, which could involve adding outsoles made of leather, more 3D-printed plastic, or even mood-sensing color-changing LED lights.

“In like ten years, people are going to look back at 3D printing today and laugh, in the same way that we look back to the beginning of the internet and say ‘that was cute,'” Schouwenburg said.