No sun, no wind, no problem: How one plant makes renewable energy reliable

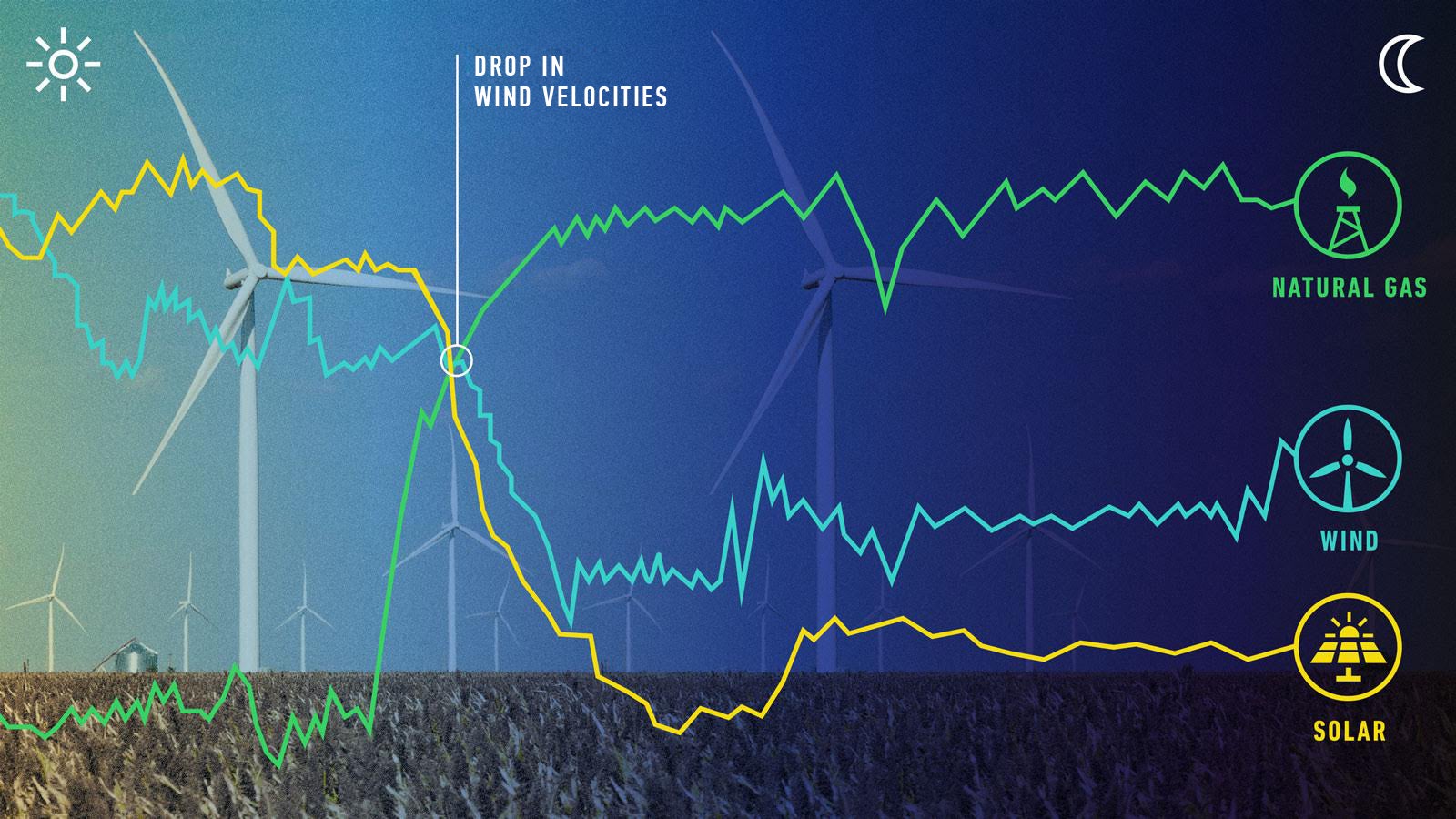

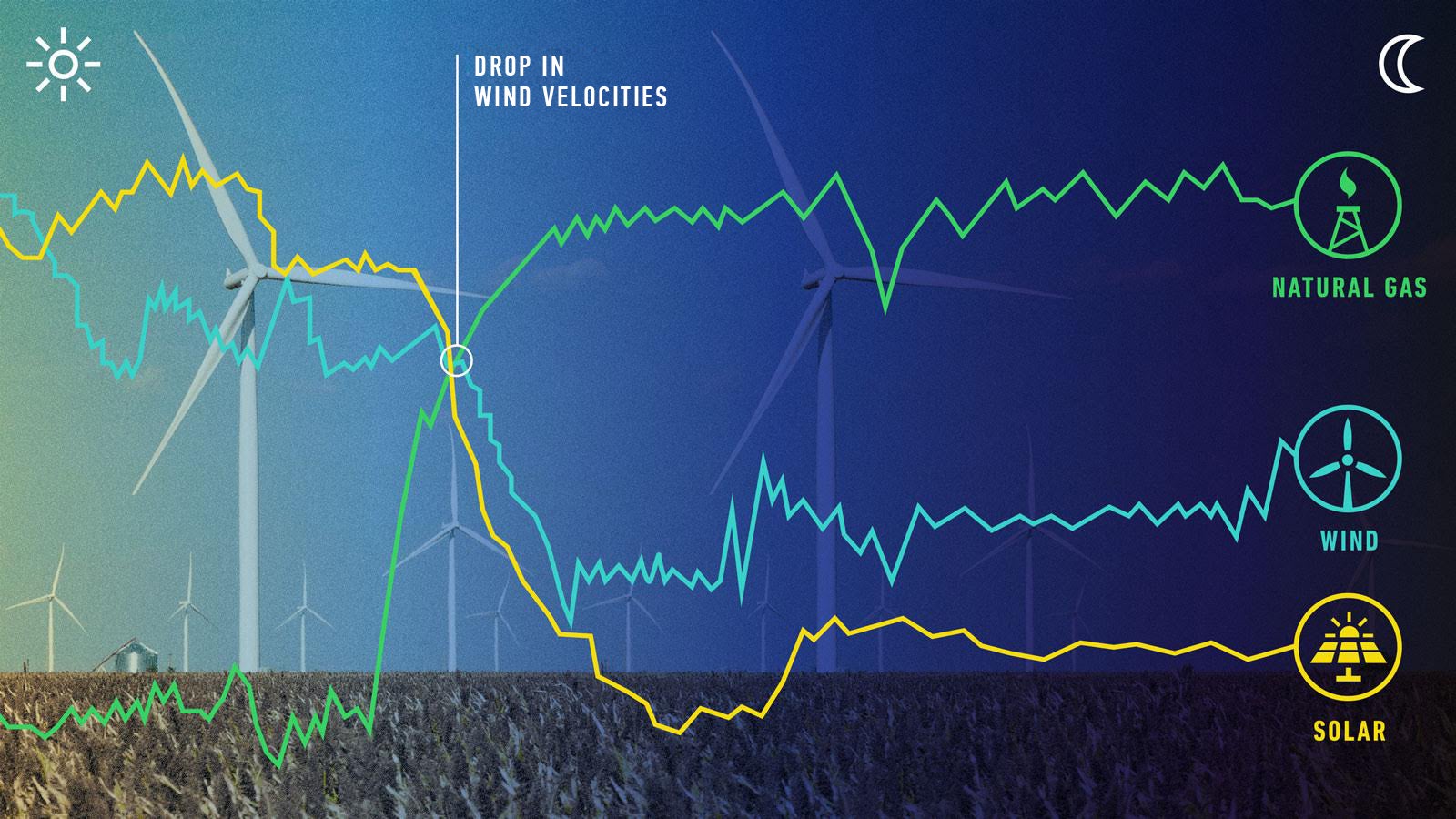

It’s not just wind turbines and solar panels powering our renewable energy future. The innovations that keep the lights on when the breeze dies and the sun hides are just as important. That’s when a different kind of breakthrough technology gets to flex.

It’s not just wind turbines and solar panels powering our renewable energy future. The innovations that keep the lights on when the breeze dies and the sun hides are just as important. That’s when a different kind of breakthrough technology gets to flex.

“You’ve got to have a flexible plant that can ramp up and down based on the solar and the wind’s variability in delivering energy to the grid,” says a night shift team member at California’s Lodi Energy Center (LEC). The Siemens Flex-Plant technology installed at the Lodi plant is a prime example of a combined cycle power plant that integrates renewable and non-renewable power generation technology to deliver reliable power regardless of the weather.

In a simple cycle power plant a gas turbine, which uses natural gas as a fuel, is used to power a generator that converts the rotating energy of the gas turbine into electricity. In this cycle, air and gas enter the gas turbine, and hot exhaust air is released.

With a combined cycle power plant, this cycle is paired with a steam cycle. The hot exhaust air from the gas turbine is used to boil water using a Heat Recovery Steam Generator (HRSG). This steam powers a steam turbine that in turn powers another generator, creating more electricity. The steam turbine’s energy is coming from the heat in the gas turbine exhaust, so you get more electricity without using any additional fuel—and less fuel means lower greenhouse gas emissions.

The higher output of a combined cycle has generally required longer startup times than a simple cycle. Yet the Lodi Flex-Plant maximizes energy production without agility tradeoffs. It’s an essential capability for not only absorbing the fluctuations of renewable energy, but also for meeting California’s strict renewable energy standards.

California’s US-leading goal to reach a 33% renewable energy portfolio by 2020 may soon become a 50% goal for 2030. The natural gas-fired Lodi Energy Center will help achieve these goals by backing up renewable energy with gusto—ramping up to 200 megawatts in thirty minutes—while remaining one of the cleanest and most efficient US fossil fuel plants. It even treats and repurposes wastewater from the nearby town as a coolant.

“Siemens Flex-Plants start fast and ramp fast, offering the flexibility of a simple cycle with the efficiency and low greenhouse gas generation of a combined cycle,” says Bonnie Marini, Siemens Energy Director of 60 Hz Product Line Marketing.

“It’s a game changing technology all combined into one plant,” Martin Tartibi, Head of Gas Turbine Power Plant Solutions Americas at Siemens Power and Gas, says in this video.

Operated by the Northern California Power Agency and jointly owned by the NCPA and local power entities, Siemens remained very involved as LEC hit the grid. Networked instrumentation allowed Siemens to provide feedback and support from its Orlando service center after launch—and the impact of Flex-Plant technology soon became clear.

It’s a proposition that’s set to delight the hearty yet eco-conscious energy appetites in California—and wherever demand for renewable energy is growing.

This article was produced on behalf of Siemens by the Quartz marketing team and not by the Quartz editorial staff.