This trailer was built to educate a new generation of engineers and technologists

In 1982, the Commodore 64 hit the market. Because it was cheap (it cost $595), and had a massive amount of storage (64KB of memory), the introduction of the C64 forced other tech companies to slash prices. All of a sudden, people could afford computers. The C64 single-handedly ushered in an early era of personal computing.

In 1982, the Commodore 64 hit the market. Because it was cheap (it cost $595), and had a massive amount of storage (64KB of memory), the introduction of the C64 forced other tech companies to slash prices. All of a sudden, people could afford computers. The C64 single-handedly ushered in an early era of personal computing.

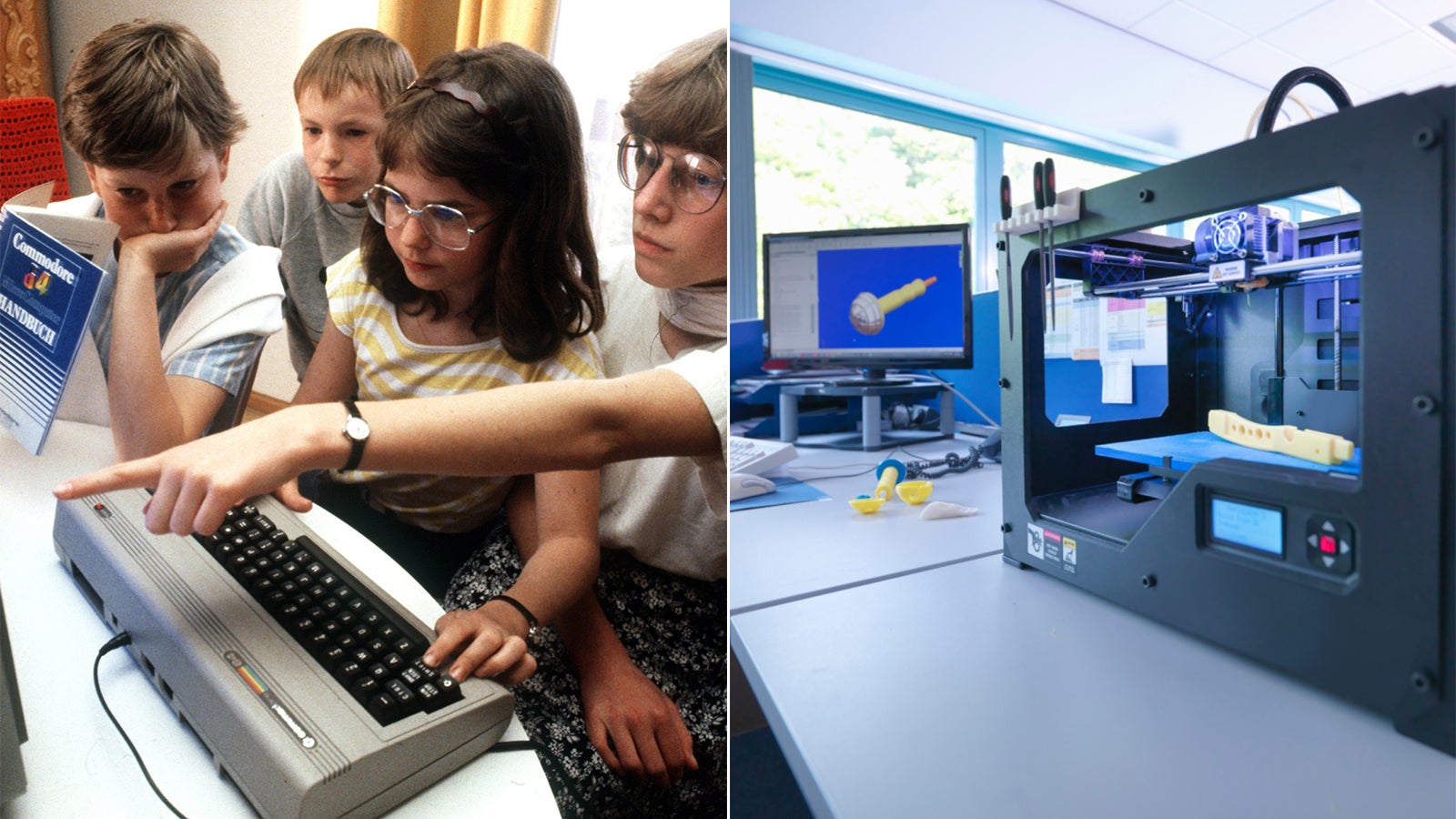

More importantly, though, the C64 taught a generation of young minds a very special, very new skill: coding. Those earlybird programmers grew up to become today’s tech leaders. Take, for example, Ayah Bdeir, the founder of littleBits: When she was eight years old, her father bought her and her sisters a Commodore 64, a dot-matrix printer, and software lessons. Today, Bdeir is paving the way for a new generation of makers with her platform of electronic building blocks for creating inventions, large and small.

That was years ago. Today, there’s arguably an even greater need to provide learners with a means to develop tech solutions for human problems. The younger generation can learn from an array of high-tech gadgets, but there is no Commodore 64 for today’s 10-year-olds. For one, cutting-edge technologies—like 3D printing—are beyond the means of most school-age children.

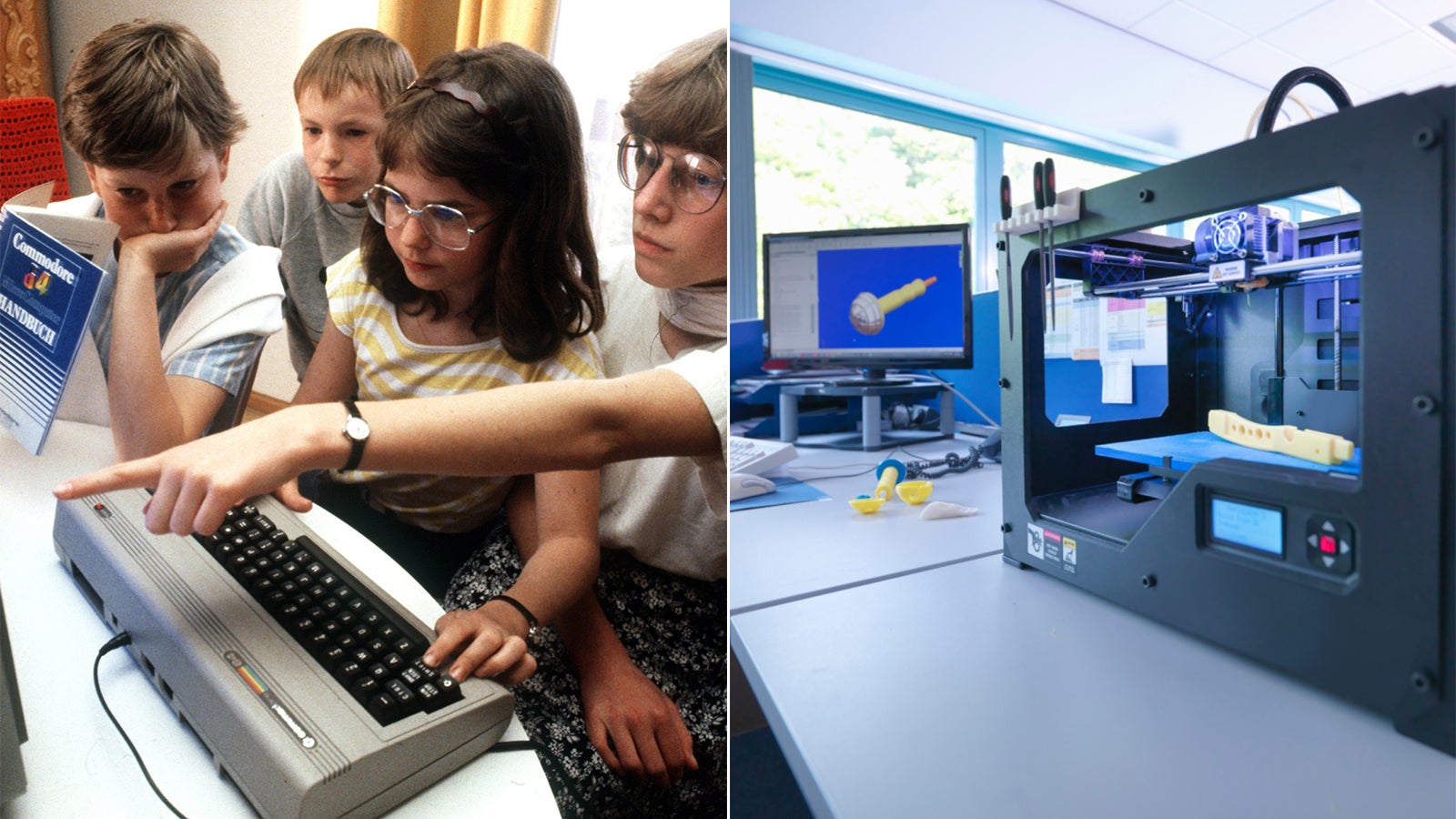

One gateway to access is TechShop Inside! – Powered by Fujitsu, a “mobile makerspace” that gives children freedom to explore a suite of technologies, including many of Fujitsu’s latest innovations. To do this, TechShop and Fujitsu outfitted the interior of a 24-foot trailer with a range of building and prototyping technologies, including six 3D printers, laser cutting and engraving machines, and Fujitsu LIFEBOOK Tablet PCs. Fujitsu’s objective is to inspire students to approach technology with a creativity that drives future insight, ingenuity, and Human-Centric Innovation: a maxim that drives the company forward.

There’s a special egalitarian streak that runs through initiatives like TechShop Inside!—another like it is SparkTruck, a Stanford d.school creation—because unlike the Commodore 64 of the past, most households today won’t have a 3D printer, or a CNC milling machine. And since all schools aren’t equipped to have maker labs on site, why not take the lab to them?

“We believe people are inherently creative; it’s a fundamental part of being human,” says Mark Hatch, CEO and founder of TechShop. That company ethos led Hatch to Fujitsu’s open innovation gateway team, who believes in a similar Human Centric approach to innovation in which technology is developed with a central objective to help people—to help them be more creative, capable, and productive. “It seems that some companies make technology their primary objective,” says Tango Matsumoto, CTO and CIO of Fujitsu, in an I-CIO Big Thinker video interview. “For Fujitsu, however, the human dimension is the foundation of our business.”

If innovation comes from people, not just machines, then Fujitsu and TechShop are making sure they get to those people early. So far, TechShop Inside! is proving that fostering human creativity can be as simple as creating access. Thousands of students in the Bay Area have already visited the mobile workshop, and “within four hours, we have 10-, 11-, and 12-year-olds designing and creating something from scratch,” Hatch says.

If today’s innovators all learned computer skills on one kind of machine—that Commodore 64—imagine what the next generation will do with an entire toolshed of machines.

This article was produced on behalf of Fujitsu by the Quartz marketing team and not by the Quartz editorial staff.