This English couple generates enough electricity for a whole village using a river that flows through their garden

Somerset, England—Back in 2002, Rachel Feilden and Anthony Battersby got the chance to buy a ruin. They snapped it up. Just a few steps from their home, it sat on a waterway running through their garden in the countryside near Bath, western England. Crucially, for what they had in mind, was its former use, a mill. Never mind that the building was roofless and reduced to a few walls.

Somerset, England—Back in 2002, Rachel Feilden and Anthony Battersby got the chance to buy a ruin. They snapped it up. Just a few steps from their home, it sat on a waterway running through their garden in the countryside near Bath, western England. Crucially, for what they had in mind, was its former use, a mill. Never mind that the building was roofless and reduced to a few walls.

Over a weekend away the husband and wife—whose day jobs involve helping improve health care in developing countries—had the idea of restoring the once-productive shell into a hydropower project, generating electricity from the flow of the river. It seemed obvious: “There was this mill that had been built to harness energy from the river, and it wasn’t doing it anymore,” said Battersby, who trained as an architect and has lived in the house by Tellisford Mill on the River Frome almost all his life.

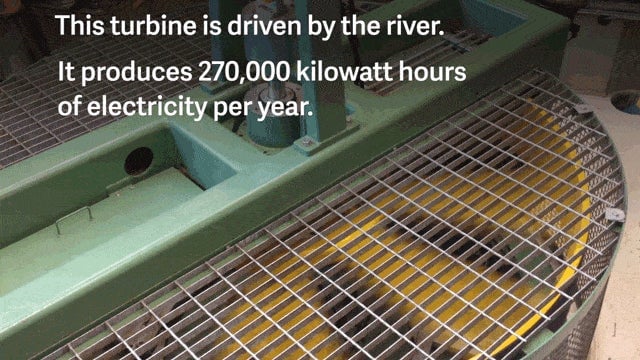

Fourteen years later, their 55 kilowatt project is up and running, powering their home and on-site offices as well as providing a handy income stream, courtesy of the surplus electricity they’re able to sell into the national grid. It has meant a huge investment of time and cash, convoluted bureaucratic battles, and—perhaps above all—a tenacious belief that it was a good idea in the first place.

As small-scale hydro pioneers in the UK, Feilden and Battersby also forged a path for others to follow, and proved that using a river to power a village is possible, even if it’s not easy. There are now 598 small hydro projects in the UK, according to data from the Renewable Energy Foundation, a charity. They range in size from tiny two kilowatt installations to over four megawatts for one Scottish scheme. This includes several others on the Frome river, and some converted mills.

Find the river

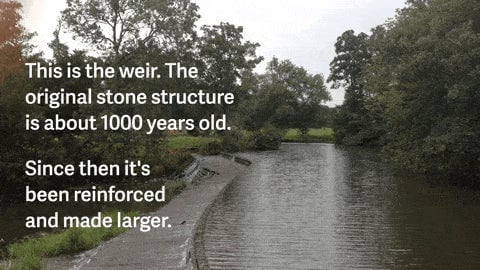

A thousand years ago, Anglo-Saxons, the people of Germanic and other tribes who populated Great Britain, knew how to harness the energy of the river at this spot.

The Saxons built this original stone weir (above), a few hundred meters upstream from Tellisford Mill, forcing a build-up of water into a “head”, which created the pressure that drove the mill wheels, turning the stones that ground grain into flour. Centuries later, it was used in the production of woolen cloth, and still later, to shred fabric for use as stuffing material. The couple’s plans would see the defunct mill generate electricity for the first time.

Hydropower schemes fall into two categories: So-called high head, where water falling down from a height drives a turbine through kinetic energy; and low head, where a difference in pressure is the key. Feilden and Battersby, wanting to maximize the amount of electricity produced, decided against restoring the 19th century turbine which was still housed in the collapsed structure, opting instead for a new Kaplan turbine.

Tellisford is a low head scheme. The difference in pressure between the upstream and the downstream sides of the installation is harnessed by shaping the turbine blades so that the distance over one side of the blade is longer than that across the other. Water flowing over the long side of the blade has to move faster than water passing over the short side; the difference in speed pushes the blades around. This kinetic energy is converted into electrical energy by a generator.

Swimming upstream

Getting the thing built was exceedingly complex and laborious. The couple spent the first year of the project dredging the leat—the Saxons’ channel for funneling some water from the river through the mill. During the second year, they dug stones out of the tailrace to allow the used water to flow unimpeded downstream.

Before construction could begin on the mill itself—on a site protected by heritage laws—they had to carefully draw up plans to preserve existing walls. They collected data to establish the flow of the water over the course of a year. At every step through the process of digging, damming, pumping, and plugging leaks, they had to meet stringent environmental standards.

Feilden recalls the years of toil with a wry laugh: “And then when it flooded, work had to stop, and you had to get the pike out of the sump,” she says, referring to a local fish that required frequent rescue from the pumping system. “It was all very hands-on.”

It cost the couple around £500,000 ($764,000), which they financed through a mixture of capital raised from the sale of Feilden’s former London home, and loans. One day, many years from now, they hope to break even.

Attack of the bureaucrats

Those who live on a body of water in the UK have “riparian” rights, the reasonable use of the stream or lake on their land. But making commercial use of a river requires more complex permissions. In the early 2000s, when renewable energy in its modern form was nascent, UK government bodies, including national and local planning, energy and environment agencies were only just getting their heads around new requirements.

Feilden and Battersby describe a process that spanned years and involved confusing communication, mountains of paperwork, long delays in decision making, and subsidy regime changes.

“The bureaucracy, to us, is the biggest risk,” said Feilden, recalling an instance when they were suddenly refused permission to proceed with the project even though it was already well underway. (That decision was subsequently reversed.) Some setbacks were brief, like when the UK Environment Agency insisted that “eel pipes” be included in the turbine design to prevent eels and baby eels from getting into the mechanism. Others were expensive. In 2015, the surprise removal of a subsidy, the Levy Exemption Certificate, cut 9% off their yearly income.

But none of this deterred them. Today, Tellisford throws off revenue of £27,000 a year, including a government subsidy which will last 20 years.

“We knew it was a long-term project. We knew the thing would run for at least 50 years if not 100 years, once it was done,” Feilden says. “So what’s between 15 years to break even or 17 years to break even? It hardly makes a difference in the long term. So if you enter it with that luxury of not having to pay dividends to anybody, you’ve got the flexibility to take the risk.”

You are not alone

The couple’s experience has helped smooth the path for those who came after the earliest adopters. They secured a grant to help set up a network of projects across the country, which they hope will be up and running soon. A 2010 report from the British Hydro Association identified over 1600 possible sites.

“There are as many different ways of people doing it as there are sites,” said Battersby.

At the time of the Norman conquest of Britain in 1066—which Tellisford Mill pre-dates—there were upwards of 5,000 mills on the UK’s rivers. Today, gradually, more and more people are going back to the old ways, this time with the benefit of some new technology.