These robots can teach each other how to pick up anything

It’s surprisingly hard for robots to learn how to get a really good grip on unusual-shaped objects. But researchers are working on a clever way for robots to share their learning with other robots over the web. This is good news, and not at all creepily dystopian.

It’s surprisingly hard for robots to learn how to get a really good grip on unusual-shaped objects. But researchers are working on a clever way for robots to share their learning with other robots over the web. This is good news, and not at all creepily dystopian.

Robots move around in strict response to their programming. But while advanced robots like Asimo or Petman have dazzling walking skills, these clever androids and their simpler production-line siblings share a problem. They can’t easily pick up any old object unless they’ve been programmed to know how to. So where your simple human hand can easily grip a screwdriver or snatch an awkwardly-shaped piece of Lego off the rug, a robot wouldn’t necessarily know how to.

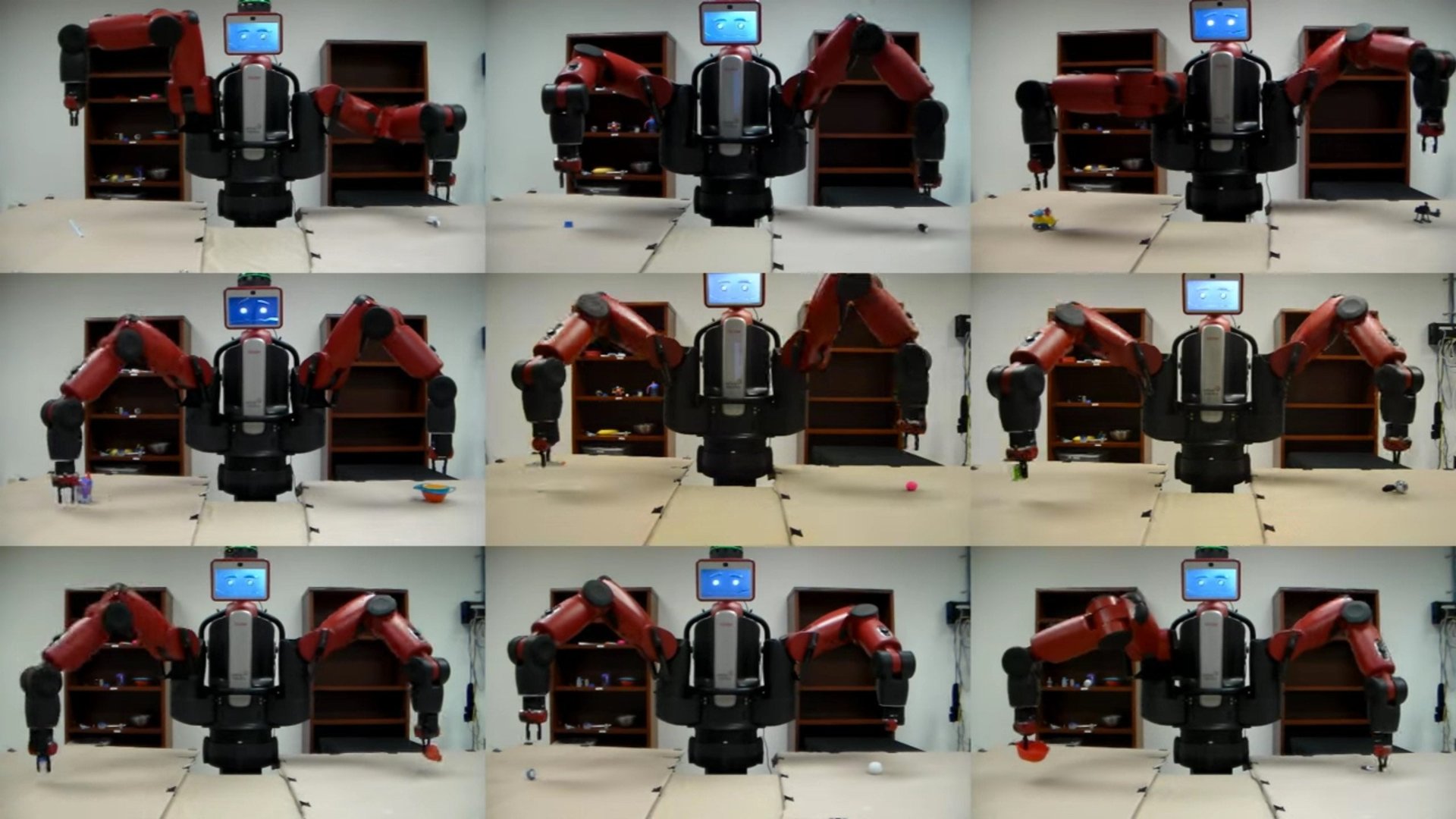

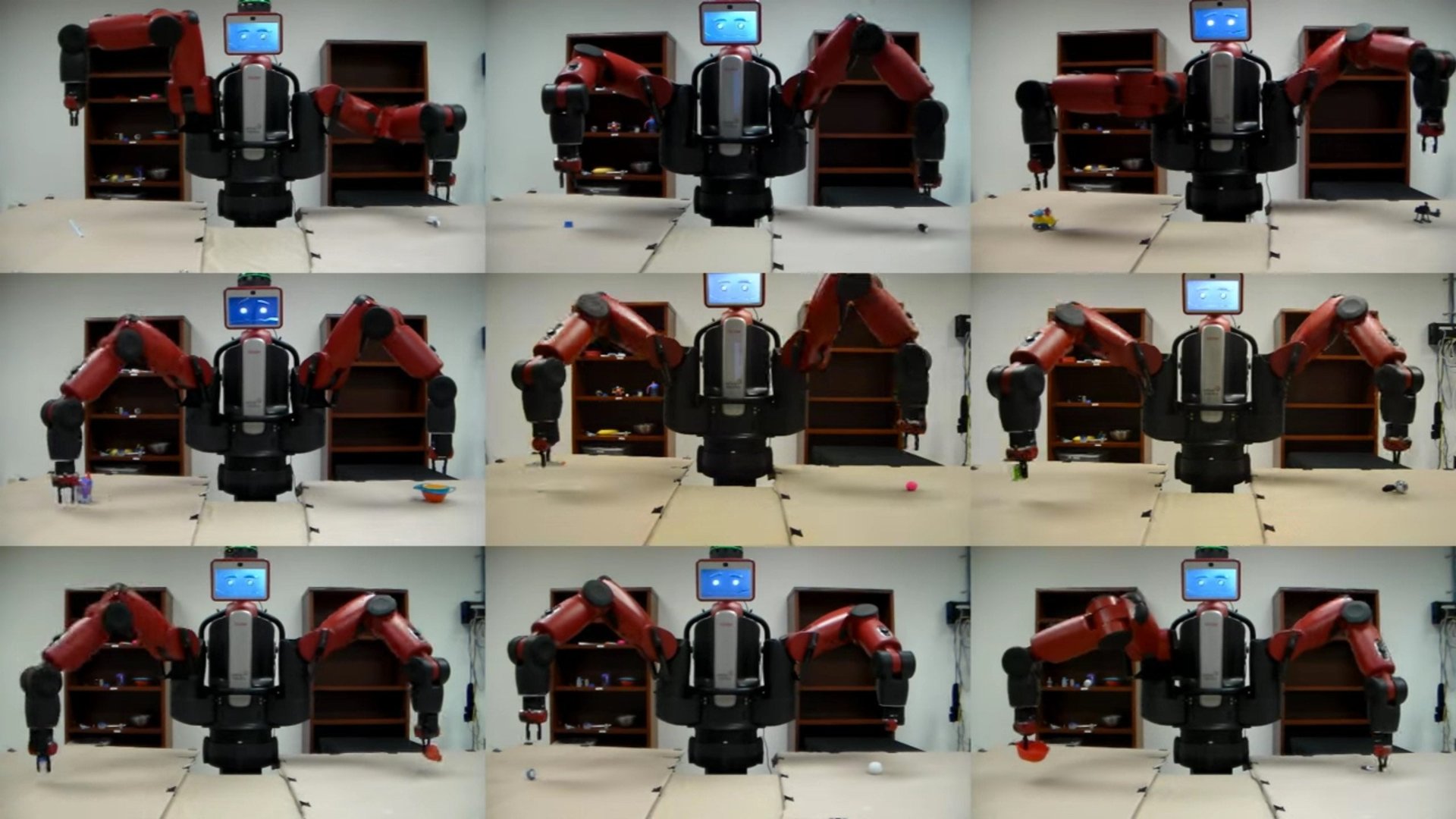

Brown University researcher Stefanie Tellex has been working on this problem, and with the help of a two-armed robot called Baxter, she is working out how to teach a robot to grip objects and then share its expertise with another robot elsewhere. The idea is that once one robot has learned how to best pick up a tricky-shaped item, other units will automatically know how to grip them when they encounter one.

When it encounters a new object it has to pick up, Tellex’s robot first scans it from different directions with infrared sensors. When it has a sense of the object’s shape, it mathematically tries out a number of different ways its hands could grip it, optimizing as it goes. Once happy, Baxter tries out the optimal grip by attempting to pick up the object, and usually this goes quite well: Picking things up is apparently 75% more reliable this way than using the machine’s basic routines (pdf).

The other clever bit is the networking, which means many Baxters working in concert could teach each all the others, quickly building a vast catalog of grip knowledge.

Gripping things without dropping them is a critical task for robots in many lines of work, from Amazon’s warehouses to electronics factories. Recent breakthroughs in robotics have even seen the arrival of Tally, a robot can that stalk the aisles of a supermarket and reliably audit stock. Thanks to Tellex’s work, future Tallys may even be able to restock shelves too, gripping all manner of trickily-shaped cans, boxes and bags of stuff.