A rare, behind-the-scenes look at Tesla’s Gigafactory

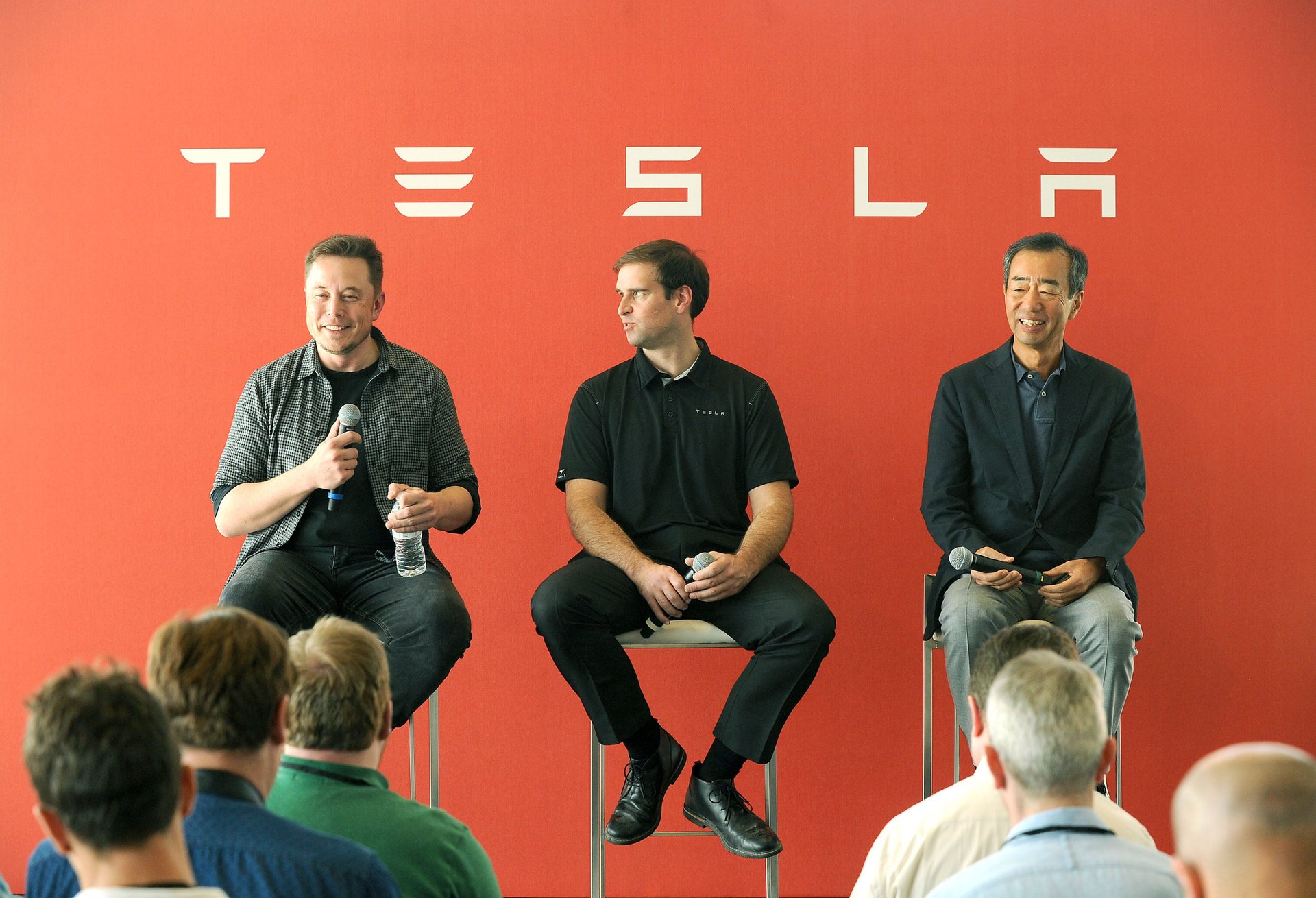

Elon Musk is building his dream factory in the Nevada desert. “I find this to be quite romantic,” he said during an interview session at the Gigafactory on Tuesday. “It feels like the Wild West.”

Elon Musk is building his dream factory in the Nevada desert. “I find this to be quite romantic,” he said during an interview session at the Gigafactory on Tuesday. “It feels like the Wild West.”

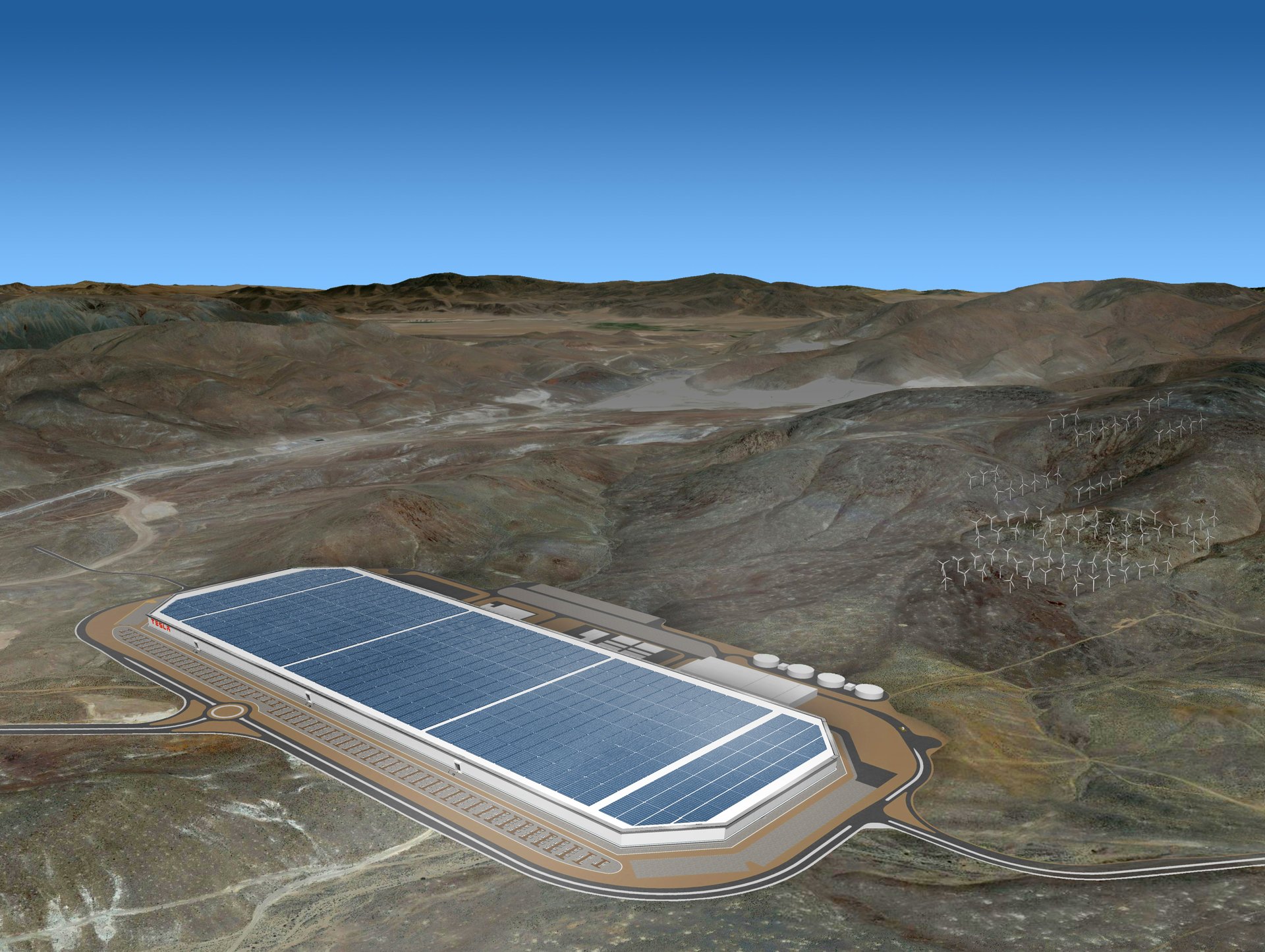

Located 24 miles outside of Reno, the Gigafactory is slated to be the largest building in the world (by footprint) once it’s completed sometime in the future, measuring 5.9 million square feet, about the size of 107 football fields. It’s needed to house Tesla’s outsized ambitions to build the world’s largest, most efficient battery factory, delivering 35 gigawatt hours of lithium-ion batteries each year by 2018, more than total worldwide production just a few years ago.

Like most of Musk’s dreams at the moment, only a fraction of the Gigafactory is complete (14% to be exact, says Tesla).

Quartz toured the facility on Tuesday, one of the first public viewings. ”Top secret” signs are still taped to windows where Panasonic is racing to install battery manufacturing equipment (the Japanese firm is a joint venture partner in the Gigafactory). Many of the rooms are wreathed in plastic sheets. A small core of Tesla workers are there reworking digital blueprints to accelerate the factory’s expansion two years ahead of schedule to meet demand for Tesla’s new Model 3 vehicle. Others are putting final touches on battery packs already being assembled for the company’s energy storage products, the Powerwall and Powerpack.

Nearly every square inch of the 3,200 acre site is marked out for future expansion. Tesla plans to spend upwards of $5 billion to finish it. We pulled together a few highlights from an afternoon at the Gigafactory.

Entering the Gigafactory

The road to the Gigafactory passes through miles of desert outside Reno. The landscape has little more than arid scrub, wild horses, and the occasional shipping depot. After turning up One Electric Drive, the scene shifts into one of constant motion. Cranes, surveyors, and earth movers move across a site under construction since 2014. Then comes a white, immaculate structure with a bold red stripe running across the top story of the building. It’s surrounded by acres of graded dirt, 10 times the area of the building, and hundreds of steel beams ready to be raised for the next expansion.

Welcomed by the Model 3

Enter the Lobby

The Gigafactory’s ceilings rise more than 70 feet high in places to accommodate the enormous equipment Panasonic must install. Musk has taken advantage of the sweeping dimensions to design an all-white and red lobby that splashes Tesla’s logo to the sky. It has added a “1” after the Gigafactory. Musk says he wants to build a Gigafactory on every continent where there is sufficient demand.

Design touches everywhere

Battery pack manufacturing is already underway

A few robots are ready

Laying down steel

Step on the electrons

Factory expansion in high gear

Building Section D

Walking through the Tesla factory brings visitors from polished concrete cleanrooms, sealed tight against elements that might ruin a battery, to areas where bare steel beams jut from the existing structure. Tesla plans to dissemble the factory’s exterior wells and move them outward as the expansion continues. Here, the southern side of the building, known as Section D, where lithium ore will enter the facility for processing into batteries, is under construction.

Securing against earthquakes

Musk’s big hopes

A finished Gigafactory, imagined

Tesla says it will expand the Gigafactory incrementally to learn and improve its processes along the way. While slated to produce 35 GwH of batteries annually by 2018, the site could eventually manufacture three times New York city’s annual energy consumption (150 Mwh), assuming sufficient demand, says Musk.