Where efficiency is discovered

For aeronautical engineers, an efficient blueprint doesn’t guarantee an efficient aircraft. You have to actually put the plane in the sky to determine the real savings. That’s the principal understanding that inspired Boeing’s ecoDemonstrator program, which integrates innovative features into dedicated test planes for continuous testing and tweaking.

For aeronautical engineers, an efficient blueprint doesn’t guarantee an efficient aircraft. You have to actually put the plane in the sky to determine the real savings. That’s the principal understanding that inspired Boeing’s ecoDemonstrator program, which integrates innovative features into dedicated test planes for continuous testing and tweaking.

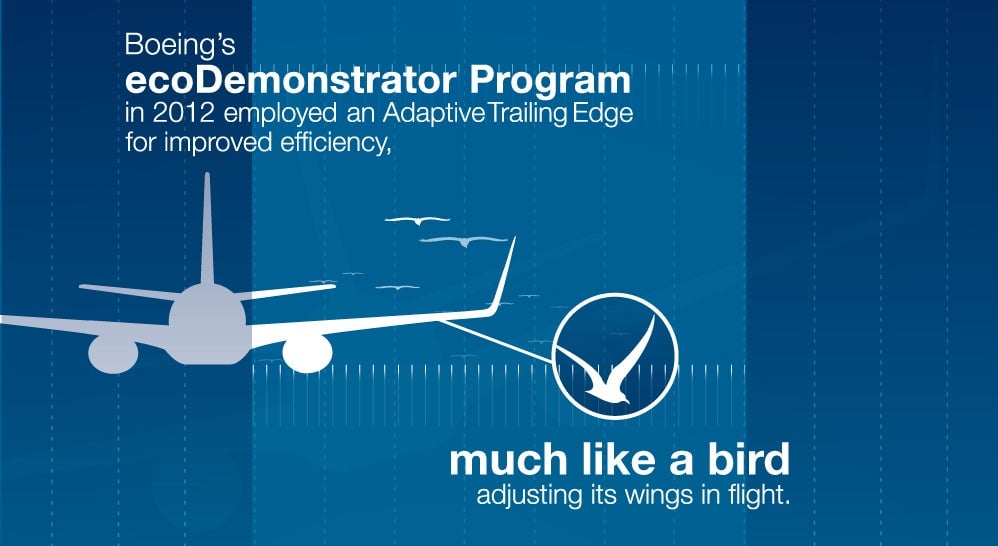

Of particular interest to the program are materials, technologies, and even flight patterns that are more fuel efficient, quieter, cleaner, and more sustainable. And these were the elements built into the 2012 ecoDemonstrator, a Next-Generation Boeing 737-800 on loan from American Airlines, which features variable area fan nozzles, active engine vibration reduction, and a regenerative fuel cell.

American Airlines is one of a handful of industry standouts to express a sincere interest in the program. After all, the savings reaped from refined efficiency are passed directly onto the carriers and could significantly improve their bottom line, as fuel is every carrier’s leading expenditure. Beyond financial savings, it is also in line with American Airlines’ mission to further reduce their carbon footprint, as well as noise pollution, and waste from their aircraft.

Another notable contribution came from the FAA program known as CLEEN (Continuous Lower Energy, Emissions and Noise), which provided funding for an adaptive trailing edge for the airplane and a portion of the flight test costs.

Boeing plans to continue the ecoDemonstrator program with new test planes every year. For 2013, they are working on a wide-bodied plane with support from the FAA CLEEN program once again. The continuation of this partnership is a promising sign for the future of this program and the future of the entire industry.

This article is written by Boeing and not by the Quartz editorial staff.