A team of graduate students just 3D-printed a speaker and it works

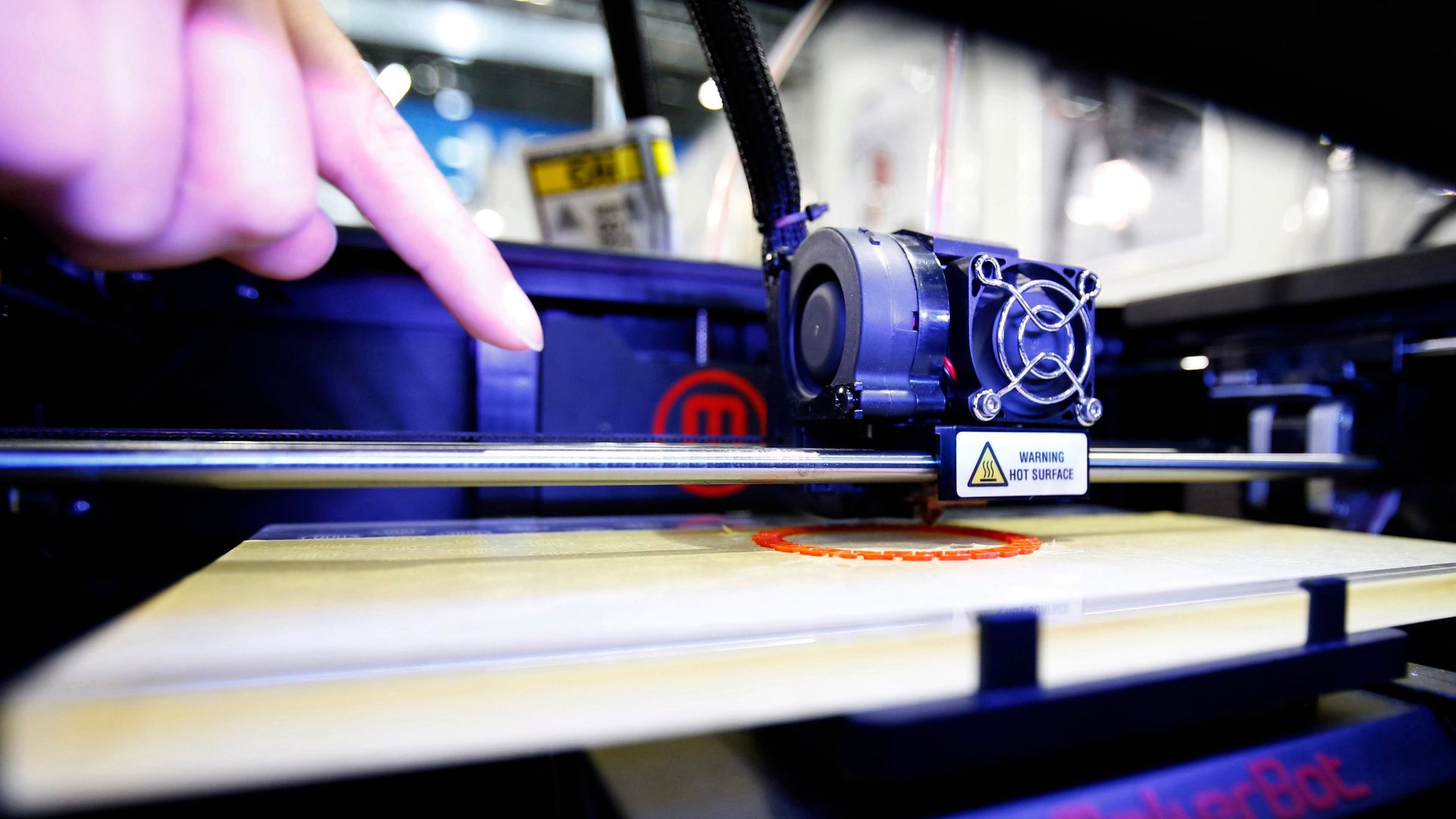

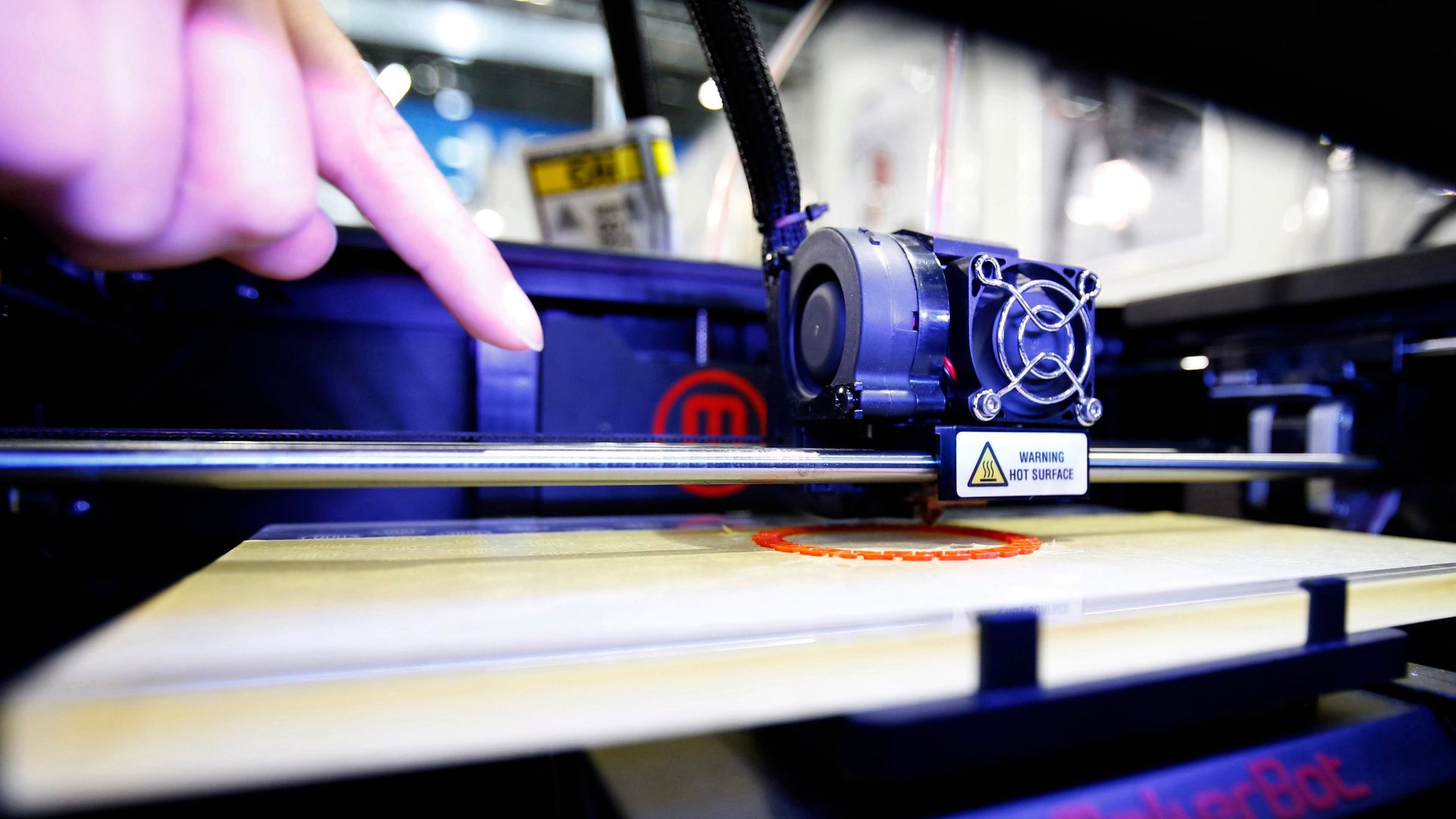

Researchers at Cornell University have managed to 3D print a loudspeaker, according to the University’s newspaper. Using two customizable 3D printers originally developed at Cornell, a team of graduate mechanical engineering students managed to almost seamlessly print the loudspeaker’s plastic, conductive and magnetic parts, producing an electronic device in two pieces that needed only to be put together to make a functional loudspeaker.

Researchers at Cornell University have managed to 3D print a loudspeaker, according to the University’s newspaper. Using two customizable 3D printers originally developed at Cornell, a team of graduate mechanical engineering students managed to almost seamlessly print the loudspeaker’s plastic, conductive and magnetic parts, producing an electronic device in two pieces that needed only to be put together to make a functional loudspeaker.

The newly printed mini-speaker was promptly shown off in a clever demo (video below), which features the gadget playing a sound clip in which US president Barack Obama mentions 3D printing during his recent State of the Union Speech. Here’s assistant professor Hod Lipson, who oversaw the project, explaining the process and showing off the product:

This is by no means the first time a single object has been printed out of multiple materials—indeed, there are even commercially-available printers that can combine a variety of plastics. And the same lab in 2009 3D-printed a telegraph machine. But combining metallic, magnetic and plastic substances in a single object is particularly tricky because of their different properties and melting points. It marks another small step in the industry’s gradual shift from being able to print components of a system to being able to print whole systems at once. ”It’s a little bit like a color printer,” Lipson explained. “With multi-material 3D printing we’ll be able to combine lots of different materials to create new things, new functionalities, and new material properties we haven’t seen before.”

This doesn’t necessarily mean the loudspeakers you buy at the store will soon be 3D-printed. The precision and efficiency needed to make quality loudspeakers—let alone more sophisticated electronics like computers and phones—might not be something 3D printing achieves for a while, if ever. For now, the process is more likely to complement assembly-line production than outright replace it. But given how far and fast it’s come, predicting the future is foolish. “We’ve only seen the tip of the iceberg of this technology,” Lipson said.