With the 3D printer revolution slow to reach the household market, MakerBot regroups

In the lobby of MakerBot’s office is a framed issue of the Economist, featuring a cover story about the rise of the 3D printing industry. It’s from 2013, when MakerBot was the pride of the burgeoning consumer 3D printing market.

In the lobby of MakerBot’s office is a framed issue of the Economist, featuring a cover story about the rise of the 3D printing industry. It’s from 2013, when MakerBot was the pride of the burgeoning consumer 3D printing market.

Last month, the company laid off about 20% of its staff and closed its three retail stores, in New York, Boston, and Connecticut. Was it all just hype?

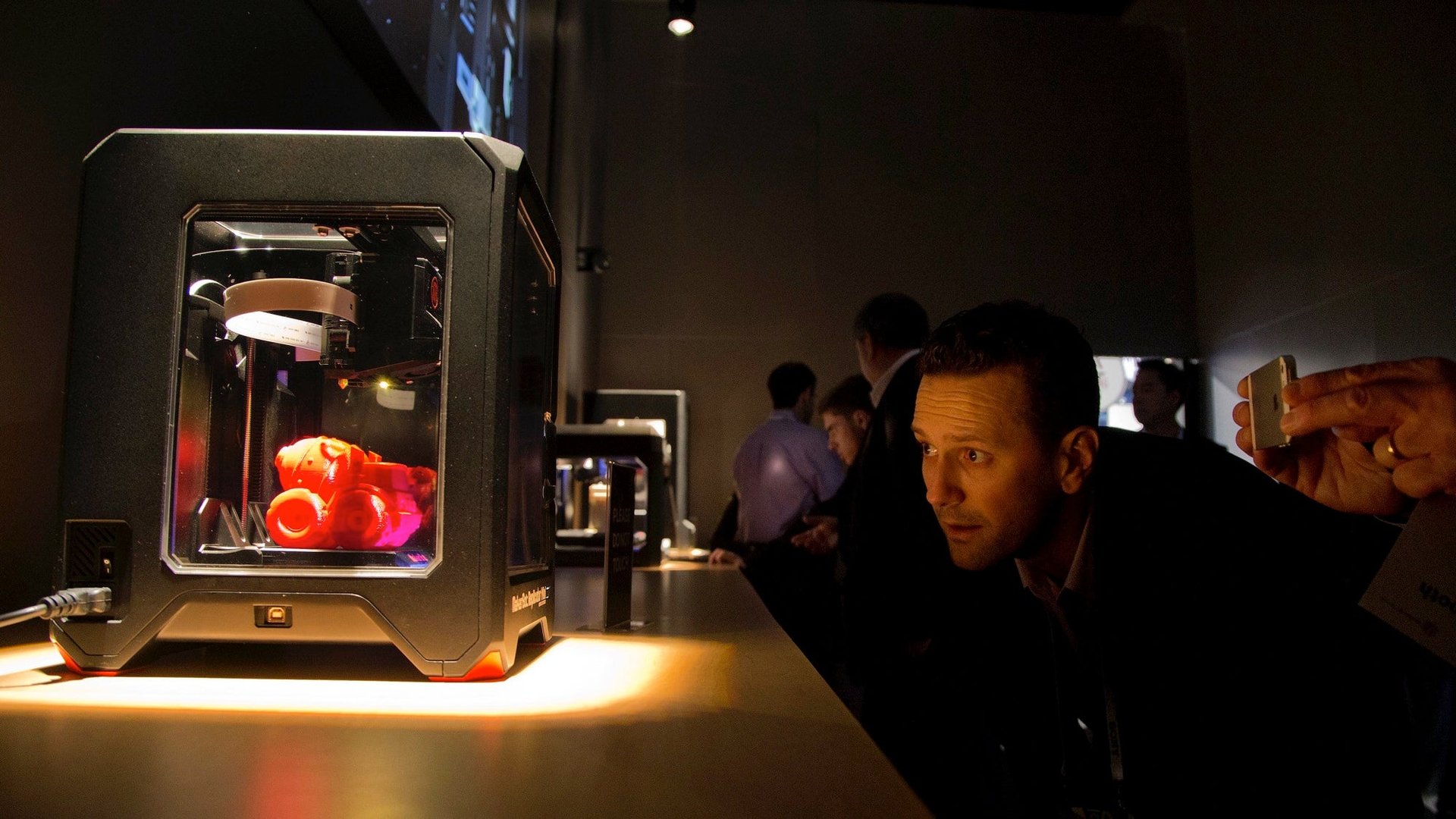

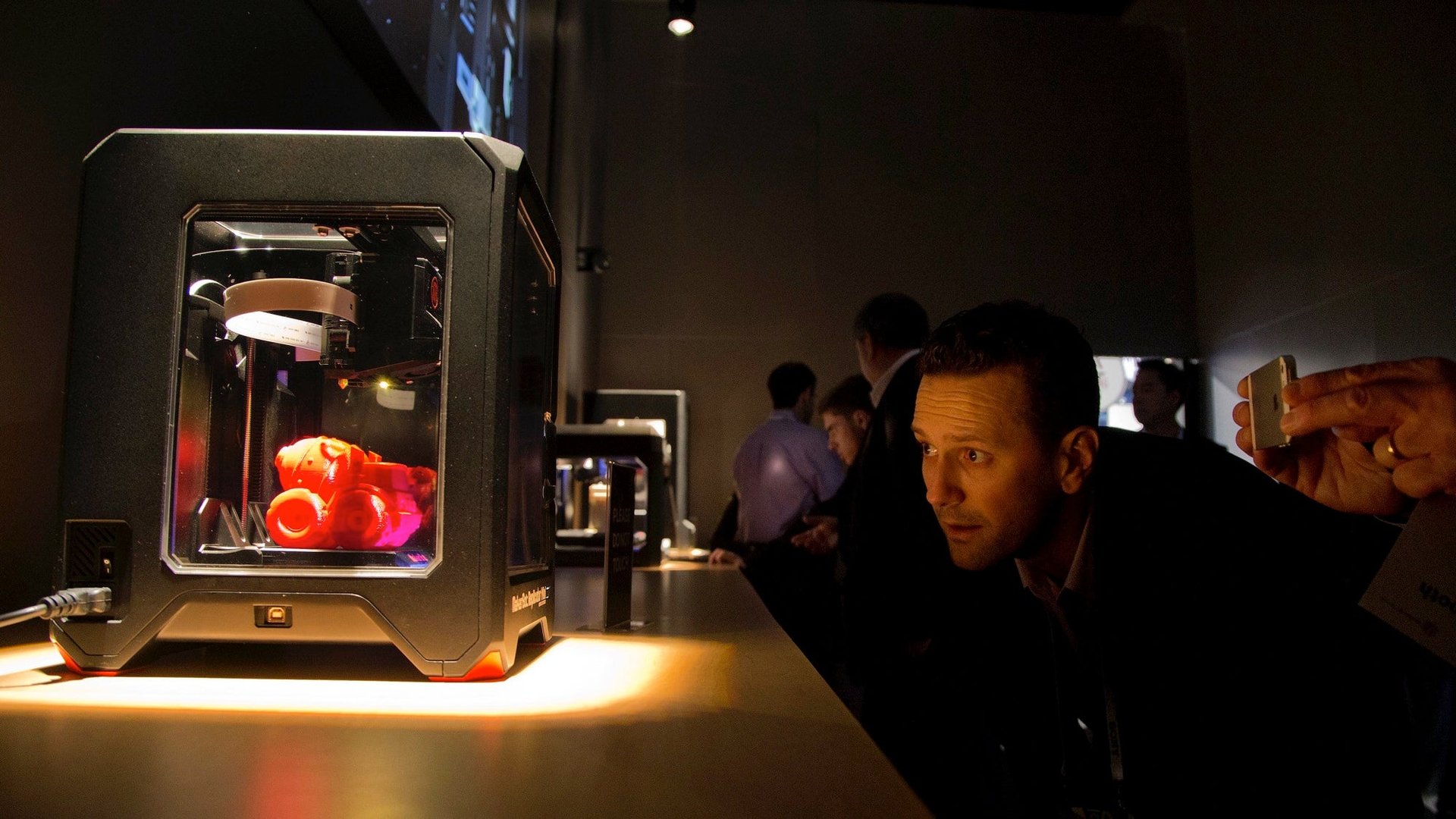

Not exactly. MakerBot has sold nearly 80,000 printers to date, and its online model repository, called Thingiverse, is still registering roughly 1 million 3D-design downloads a week. But 3D printing technology remains too slow, too expensive, too techie to have much mainstream appeal, which is why MakerBot is setting aside its aspirations for the home market and focusing instead on the education and professional markets.

MakerBot says its printers are in more than 5,000 US schools already, and CEO Jonathan Jaglom is determined to get as many printers into as many school districts and universities as possible. Growth in this market will depend in large part on MakerBot’s ability to educate educators. To that end, the company has developed starter kits geared toward academic settings and says it will soon be producing curricula to help teachers create 3D models.

“The founder of MakerBot—the initial audience of MakerBot—these were tinkerers, these were makers,” Jaglom says. “But the schoolteacher in Ohio—she’s not.”

It’s easy to imagine how 3D printing might revolutionize visual learning. During our recent visit to MakerBot, company spokesman Johan-Till Broer showed Quartz a 3D-printed model of a Tyrannosaurus Rex skull and a model of an outboard motor, and told us about a history teacher who had 3D printed a diorama of Pompeii to show his students how the lava had flowed through town. No doubt the 3D-printed Pythagorean theorem model that Jaglom keeps on his desk—like this one— would be useful to math students struggling to see how the square of one side of a triangle can be as big as the squares of the other two combined.

Commercial appeal

Jaglom also sees potential for MakerBot 3D printers in designing and prototyping, purposes that span both the education and professional markets. ”Ten years ago you needed to know some CAD program to design 3D models,” Jaglom said. Now you can just point a tablet’s camera at a notebook and start printing your designs.

This potential avenue for growth would potentially put MakerBot machinery under the same roof as industrial 3D printers from MakerBot’s parent company, Stratasys, which last week announced it had 3D-printed more than 1,000 parts for Airbus’ A350 XWB planes that shipped in 2014. It’s hard to think of a more definitive way to show that 3D printing is hitting its stride on the industrial side than to point out that there are 3D-printed parts in use on commercial passenger jets. But that’s from printing that’s done on a massive scale, with huge printers running virtually all the time. MakerBot printers are smaller, more personal devices. Jaglom sees MakerBot’s role in the professional market as the drawing board to Stratasys’ production line.

In the future, Jaglom says, “I would be surprised if plane manufacturers don’t have MakerBots in house.” The actual parts “might be produced by Stratasys, but maybe those parts were designed and iterated on a MakerBot.”

A printer in every living room?

Despite the change in focus, MakerBot hasn’t given up on the household market—not entirely anyway. For example, the company is exploring the use of new composite materials that could have broader consumer appeal. Broer shows off a 3D-printed hammer made of iron and wood filaments that can be printed on any of MakerBot’s current printers.

Jaglom says there could be a time when consumers print out their own hammers, nails, coat hangers, or other household necessities. But this won’t happen en masse anytime soon. Printers for the consumer market remain stubbornly slow, and MakerBot’s cheapest model costs about the same as a Macbook—not unaffordable when you think about how many people are buying Macs, but not the kind of price that allows a relatively new company in a relatively new market to make much of a splash with the average consumer. (To that end, MakerBot’s new displays at Sam’s Club discount warehouse stores will come with a “What is 3D Printing?” poster.)

Jaglom says his plan for MakerBot is “to remain disruptive,” although with competitors springing up all the time with cheaper and quicker alternatives, it will be a tough task.

“What’s left after the hype?” Jaglom asks. He pulls out his 3D-printed business card holder, displays his 3D-printed pencil holder, and points to his 3D-printed coat hook, all of which he made on his office’s printer. It was the same printer he used when, from his couch at home, he used his smartphone to print off a piece of artwork, via the MakerBot mobile app. “This is utility,” he says.

Indeed. There still could be a time when we use 3D printers in the way that had been envisioned—a printer in everyone’s living room—but that reality is taking longer than many had hoped.

“We’re big believers in the consumer market,” Jaglom says.

But at the moment, he concedes, ”we are leaps away from where we want to be.”