An Apple Car could succeed if Apple’s culture changes, and could kill if it doesn’t

Fueled by a significant number of hires from other car makers, and real estate expansion beyond the upcoming hypergalactic spaceship HQ in Cupertino, rumors of an Apple Car keep percolating. I hope to drive an Apple Car someday… but does Apple’s personal computing software know-how translate into the high-reliability, real-time code required for a safe, reliable and, of course, elegant electric car?

Fueled by a significant number of hires from other car makers, and real estate expansion beyond the upcoming hypergalactic spaceship HQ in Cupertino, rumors of an Apple Car keep percolating. I hope to drive an Apple Car someday… but does Apple’s personal computing software know-how translate into the high-reliability, real-time code required for a safe, reliable and, of course, elegant electric car?

When discussing the heavily-rumored Apple Car, software expertise is one of the company’s oft-cited advantages in its attempt to make a dent in the car industry. Look at how OS X continues to help the Macintosh grow while the PC industry contracts. Look at the billion high-margin iOS devices. Apple’s software prowess helped the company defy conventional wisdom and propelled it to the pinnacle of the tech industry. That same expertise will naturally lead to another breakthrough, in the electric car sector this time.

Indeed, there is a lot of software in a modern vehicle. Consider a partial list of software-driven subsystems in a hypothetical electric car:

- Navigation, entertainment, phone, messaging (a.k.a.Infotainment)

- Driving assistance: lane keeping, intelligent cruise control, semi-autonomous stop-and-go in traffic, collision avoidance and emergency measures, night vision, birds-eye vision

- Air-conditioning

- Stability control: anti-slip, electronic differential, one-wheel correction braking

- Suspension management, including terrain reading and GPS assistance

- Steering: adjustable feel, feedback and alerts, side-wind assistance

- Battery management: charging, cooling, kinetic energy recovery

(Electric car designers are lucky that they don’t have to deal with a gasoline engine’s complications: ignition control, fuel injection, cooling, lubrication, turbo compressor, exhaust re-circulation, catalytic converter… In one of my techporn fantasies, an Engine Control Unit (ECU) engineer takes me for a stroll through the source software for this complex but reliable real-time system. No spinning beachball allowed here.)

Proud incumbent automakers look down on the interlopers. Dr.-Ing. Dieter Zetsche, head of century-old Daimler-Benz, has no patience for Silicon Valley companies intruding on his turf:

“What is important for us is that the brain of the car, the operating system, is not iOS or Android or someone else but it’s our brain […] We do not plan to become the Foxconn of Apple,” Mr. Zetsche said, referring to the Chinese company that manufactures iPhones.

Bob Lutz, another illustrious and outspoken car company exec (GM, BMW, Ford, Chrysler), has no kind words for Apple’s rumored car project: “When it comes to actually making cars there is no reason to assume that Apple, with no experience, will suddenly do a better job than General Motors, Ford, Volkswagen, Toyota, or Hyundai. So I think this is going to be a gigantic money pit…” “By the way the electric car market is still miniscule. That just doesn’t make sense.”

Well… Messrs. Zetsche and Lutz might want to meditate on Palm CEO Ed Colligan’s infelicitous words mocking the newborn iPhone in 2006 [emphasis mine]: “We’ve learned and struggled for a few years here figuring out how to make a decent phone. PC guys are not going to just figure this out. They’re not going to just walk in.”

What Ed Colligan got wrong was that Apple didn’t “just walk in.” Steve Jobs had long been fascinated with phones. He had started a MacPhone project as early as 1984; three years later, he tried to convince Eric Benhamou, CEO of 3Com, to hand over Palm (owned by 3Com at the time). And the iPhone itself was hardly a weekend hack; the project started in 2002, an offspring of the company’s “035” tablet experiment (Jobs: “I thought, ‘my God, we can build a phone with this!’ So we put the tablet aside, and we went to work on the iPhone.”)

If the rumors are more or less correct, Apple started working on various car projects at least two years ago. The 2019 date (admittedly poorly sourced) would put the company’s electric vehicle project on a fix or six year development cycle.

While we can sympathize with Zetsche’s and Lutz’ defiance, on the topic of user interface—an element that’s becoming increasingly important in car design—they and their industry colleagues could learn a lot from Silicon Valley. Just try to pair a phone with one of their vehicles, or maneuver through the clock menu twice a year to (manually!) shift between Standard and Daylight Saving Time, something that even Comcast does automatically. Car navigation systems lag behind what you get using your smartphone—and you have to pay $149 or so for an update. To quote my engineer friend Joseph Palmer: ‘It costs more, but it does less.’

High-end cars are loaded with interesting and genuinely useful features, but they’re hard to find, understand, and manage through the variety of screen messages, buttons, and levers. I just checked: The user manual for my five-year old car is 544 pages long.

To their credit, newer cars offer user manuals in app form, but, unfortunately, they’re hardly impressive. I just downloaded the guide for my next vehicle and spent a good deal of time browsing through it. With its poor design, cramped typography and graphics, and sloppy organization, the guide looks like a cheap outsourced job, not the work of a world-class car maker—one that’s perhaps a bit too quick to dismiss Silicon Valley know-how.

Of course, there’s more to a car than UI and user manuals.

Consider the complicated, contradictory tasks that are controlled by the Electric Power Steering system (EPS). Sensors, electric motors, gears, and software make it easy for you to maneuver your vehicle at low effort parking speed and still maintain a straight line at highway speed with its variable return-to-center force. In a steep turn, EPS must provide sharper steering angle ratios and let you know if the car is starting to “push” (understeer), or if the back of your car is about to swing loose (oversteer).

To save your life, EPS software attempts to get between you and the front wheels, using speed and yaw information, comparing intended and real trajectories, and then applying steering and braking corrections. Take the “famous” Moose Test—an evasive left-right obstacle avoidance maneuver performed at highway speeds. Without assistance from sensors, software and electro-hydraulic actuators, most of us will either hit the obstacle or roll the the car into the ditch. At the highway speeds for which it is designed, a modern EPS, in collaboration with the braking subsystem, will not let you roll over, regardless of your steering input.

Then there’s the battery system. Lithium-ion batteries are now used in electric cars for their favorable weight-to-power ratio (100 to 265 Watt hours/kg, compared to 33 to 42 Wh/kg for lead-acid technology, and 40 to 60 Wh/kg for nickel-cadmium cells). Besides being expensive, they can be dangerous: Because they contain a flammable electrolyte, they must be charged at temperatures not much above 45 ºC/115 °F, nor below 0 ºC/32 °F.

Also, the charge and discharge intensity must be carefully managed to avoid overheating because a battery cell inevitably acts as a resistor: The higher the current, the higher the I^2*R power dissipation (where I represents intensity, and R, resistance). This requires parallel to series switching, and, in some cases, DC to AC conversions needed to go from the 3.4 or 3.7 volts of a single cell to the hundreds of volts (375 V, AC in Tesla’s case) required to run an electric car’s power train.

More tricks are required to harvest some of the kinetic energy that’s made available when the car slows down. I write some because a substantial portion is lost as heat in the brakes, aerodynamics, and tire friction; the rest comes back as a surge of electric energy that’s often too steep for the battery system to swallow in the short time of the braking event. (See this Tesla blog for more.)

All these wondrous complications can be seen as a fertile ground for Apple’s software and integration expertise. Is this really the auto industry’s turf? How could the Cupertino company not do a better job than legacy auto companies that look at software as something they have to do versus something they love as their raison d’être?

But there’s another, more important side to the story.

While it’s easy to poke fun at Zetsche’s pronouncements and his industry’s software-as-mere-IT culture, I also have to consider that my current vehicle is more than five years old—and how many software or mechanical bugs in those five years? Null. Zero. Before that, I drove a car from the same series for four and a half years. Bugs? One out-of-the-box suspension problem that was fixed a few days later and that was it. No more problems.

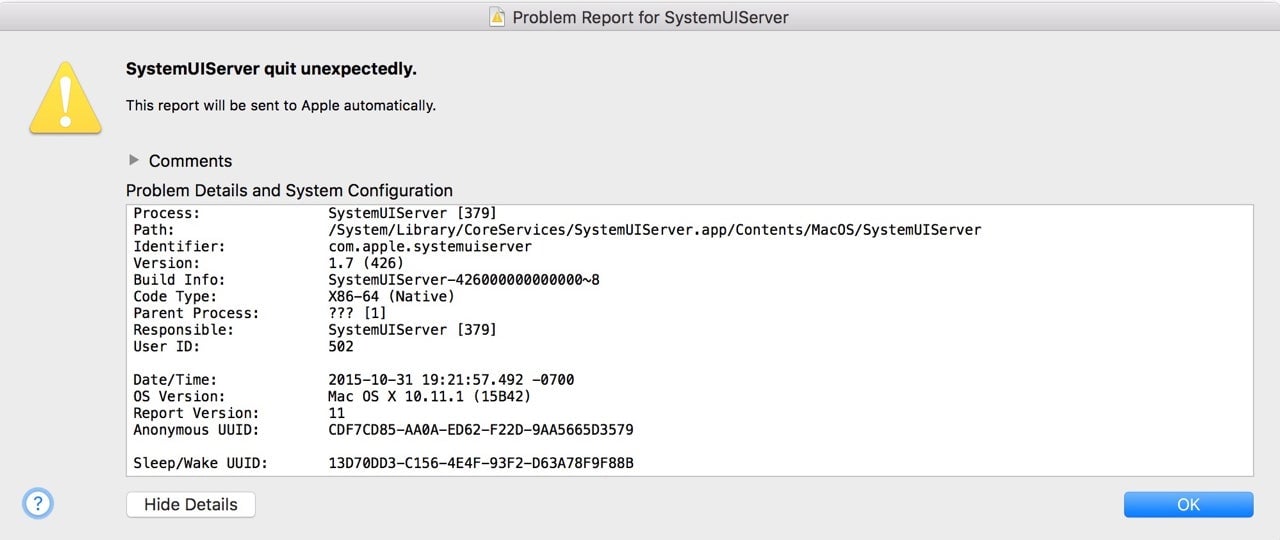

On my Mac, I tolerate the occasional screen message telling me that Mail or some other service has quit. Believe it or not, the example below just happened as I was editing this piece:

I continue without damage to my data (so far). But what we’ve grown to accept in our personal computers can’t be allowed in a vehicle carrying human beings at 60 miles per hour.

Just because the software running inside Apple’s personal computing devices is considered high quality doesn’t mean that the culture that produces it is capable of producing the high-reliability, real-time embedded software needed for an electric car.

I am one of the many who believe culture always wins. Culture eats strategy for breakfast—it causes mergers and acquisitions to fail, and, above all, it resists virile executive calls to change. Culture evolves slowly—as if having its own independent will—or not at all.

The bottom line is this: For the hypothetical Apple Car project to succeed, a necessary (but not sufficient) condition is a culture change of a kind rarely, if ever, achieved by large organizations.

Perhaps the new software culture could arise in a new, separate group, well protected against the corporate lymphocytes always prone to attack what they see foreign objects. But that would break Apple in two separate cultures, and be the beginning of a dangerous process for a company that, today, strives on having a united functional organization.

I hope Apple succeeds, and will watch for signs of change as months go by and as, in a kind of tunnel effect, information manages to leak through the company’s wall of silence.

This post originally appeared at Monday Note.