Adidas is kicking off the era of 3D-printed sneaker production with the Futurecraft 4D

Adidas has unveiled what it presented as a giant leap forward in the way sneakers are made.

Adidas has unveiled what it presented as a giant leap forward in the way sneakers are made.

The company revealed a new sneaker, the Futurecraft 4D, created with a 3D-printing process developed by the Silicon Valley startup Carbon. It says the process allows it to rapidly produce new sneaker designs and scale them up to mass-production. To start, it expects to release 5,000 pairs this year, and more than 100,000 by the end of 2018. That’s not a huge amount for a company that sells hundreds of millions of sneakers every year, but it’s a significant start—and it positions the company as a pioneer in mass-produced 3D-printing manufacturing.

Adidas plans to continue scaling up production through 2021. It didn’t say how much the Futurecraft 4D will cost, except to explain that it will come at a premium to start. But it says it is working to lower costs and increase manufacturing capacity.

The real benefits of the technology, however, go beyond just one shoe. In typical sneaker manufacturing, where the sneaker’s midsole is made with foam, the process goes: design, prototype, tooling, and finally production. Tooling involves building the metal moulds used to make the soles, and it’s expensive and time-consuming.

But now, says Gerd Manz, Adidas’ VP of technology innovation, ”once the design is finished, you press a button and you print your midsole. This is a matter of two hours. Traditionally it takes you more than a month to build a mould to build a product.”

What that means is Adidas can speedily produce new designs, test them on athletes, and then put them into production if it chooses, without any major investment in new tooling. For example, since Adidas partnered with Carbon about a year ago, it went through 50 iterations of the Futurecraft 4D before arriving at the final product.

Manz says the company foresees being able to quickly create soles tailored to specific sports, or even specific markets, and ultimately the goal is to allow a customer to be able to walk into an Adidas store and have a customized sole printed for them while they wait. (The company is already experimenting with allowing shoppers to get a sweater 3D-knitted to their specifications at a pop-up in Berlin.)

The German brand and its big rivals, Nike and Under Armour, have all been experimenting with 3D printing, but so far it’s been mostly restricted to creating fast, inexpensive prototypes. Adidas looks like it will become the first to put a 3D-printed sneaker into mass production.

What makes all this possible is the 3D-printing process created by Adidas’ partner in the venture, Carbon, whose investors include BMW, GE, and Nikon. Where most 3D printers fuse together layers of plastic, Carbon’s method, inspired by the T-1000 robot from Terminator 2, uses light and oxygen to create an object as it’s extracted from a pool of gooey, photosensitive resin. Here’s how Quartz technology reporter Mike Murphy has previously explained it:

A light shines through the pool of resin, which causes the resin to harden. Oxygen, on the other hand, causes the resin to liquify. Using them both in combination, a light source can be intricately controlled like a three-dimensional film projector, so only certain parts of the resin are pinpointed and hardened as the object is pulled out of the goo.

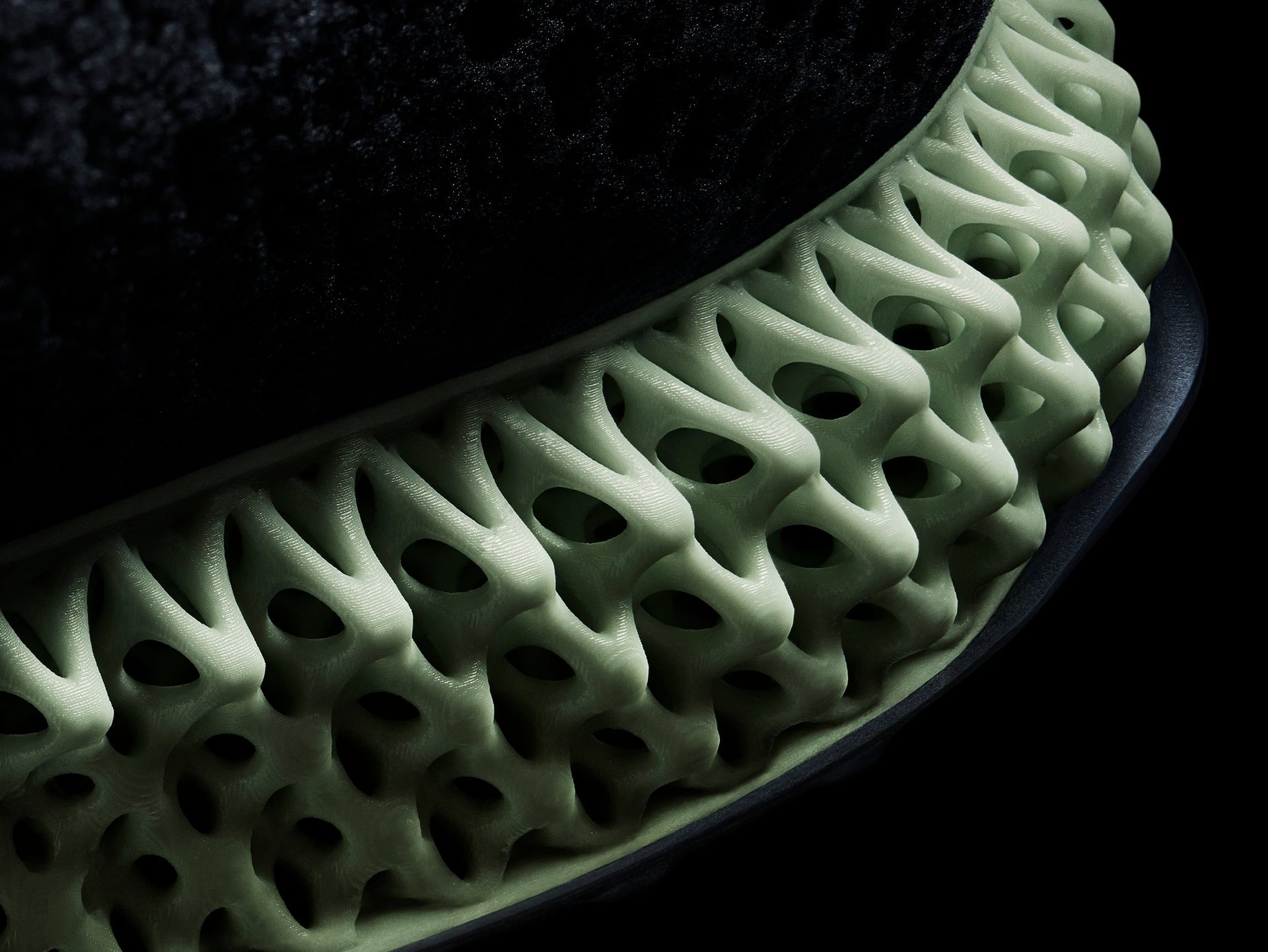

Adidas and Carbon say the process lets them create more complex geometric structures than other 3D-printing methods, allowing for better performance, since the midsoles can be designed to cushion and respond differently to specific areas of the foot. It’s faster, too—between 25 and 100 times faster than traditional 3D printers, according to Carbon CEO and cofounder Joseph DeSimone.

The final product has a smooth surface and looks like one piece, rather than the rough, layered look produced by other printers. It’s an important detail when you’re selling consumer products that double as fashion.

(Full disclosure: Adidas provided me and the other attendees of its April 6 unveiling event in New York with sample pairs to test. The sneaker is comfortable, though I haven’t noticed a significant difference in feel from some of the technologies already on the market. But I haven’t been able to run in it or do much more than walk a few steps in my apartment.)

Adidas has been experimenting with 3D printing for a few years now, but for Manz, the Futurecraft 4D marks a personal milestone. “I’m an engineer,” he says. “My thesis I wrote in ’97 about additive-manufacturing technologies. I’ve been driving so hard to get to the point to make this commercially, and that’s what we’re now achieving, 20 years later.”