One very basic job in sneaker manufacturing is testing the limits of automation

If you’ve ever bought a pair of new, unlaced sneakers you know what it’s like to lace them yourself. It requires carefully wriggling the plastic-cased end of the lace up and through the tiny holes in the shoe’s upper from the inside. Sometimes there are two layers to navigate: the cushioned textile interior and maybe a hard plastic overlay used to tighten the shoe around your foot when you tie it up.

If you’ve ever bought a pair of new, unlaced sneakers you know what it’s like to lace them yourself. It requires carefully wriggling the plastic-cased end of the lace up and through the tiny holes in the shoe’s upper from the inside. Sometimes there are two layers to navigate: the cushioned textile interior and maybe a hard plastic overlay used to tighten the shoe around your foot when you tie it up.

Of the approximately 120 steps involved in manufacturing an Adidas sneaker, that seemingly simple task is among those robots have not yet been able to master, at least not on an industrial scale, according to Adidas CEO Kasper Rorsted. ”The biggest challenge the shoe industry has is how do you create a robot that puts the lace into the shoe,” he said. “I’m not kidding. That’s a complete manual process today. There is no technology for that.”

As the Financial Times reported (paywall), Rorsted made the comments last week on his first trip to Asia as the new boss of the German sports brand, where he talked about the limits of automation, the prospects for reshoring manufacturing in Europe and the US, and how human hands are still essential in a great deal of production.

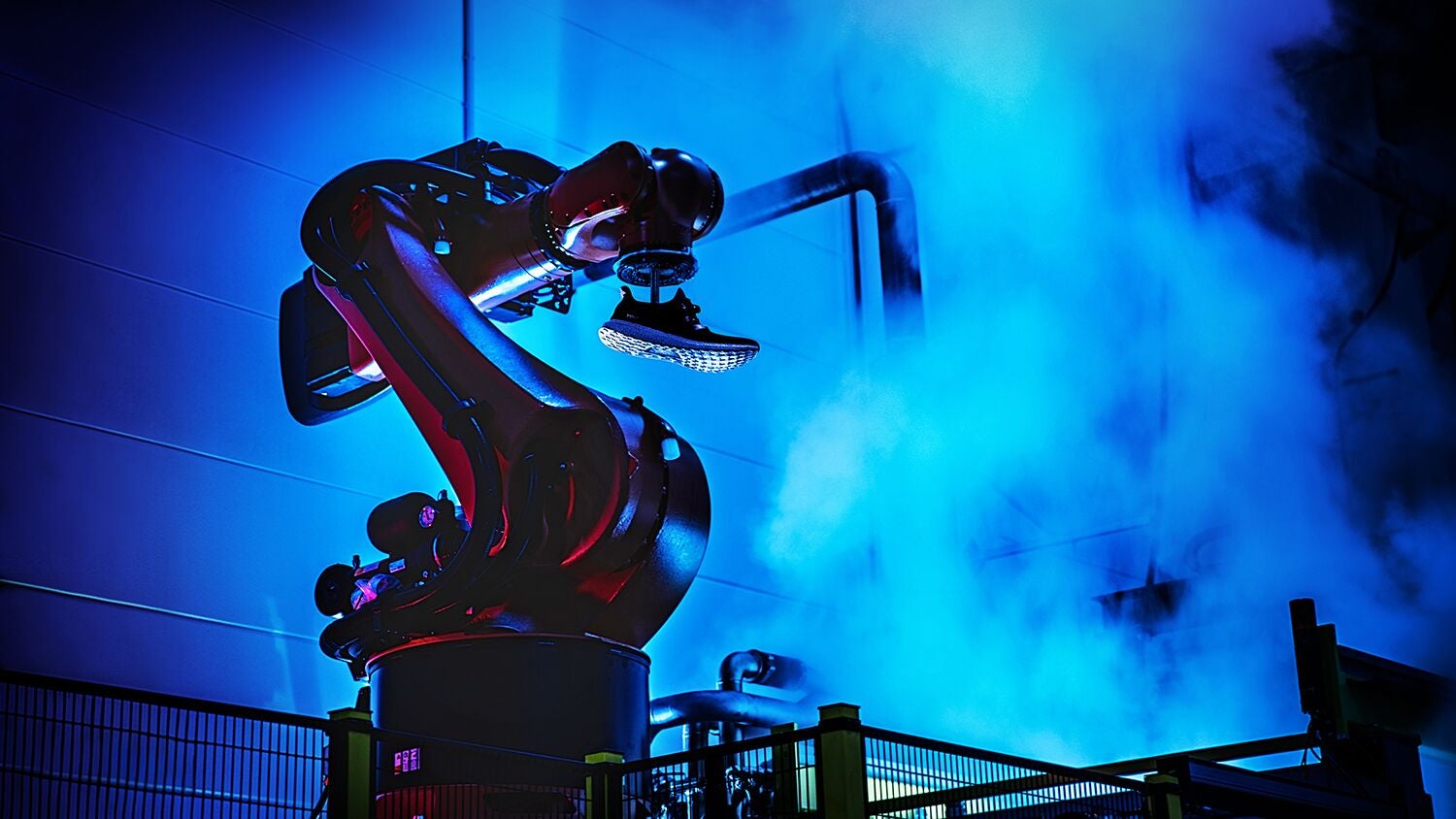

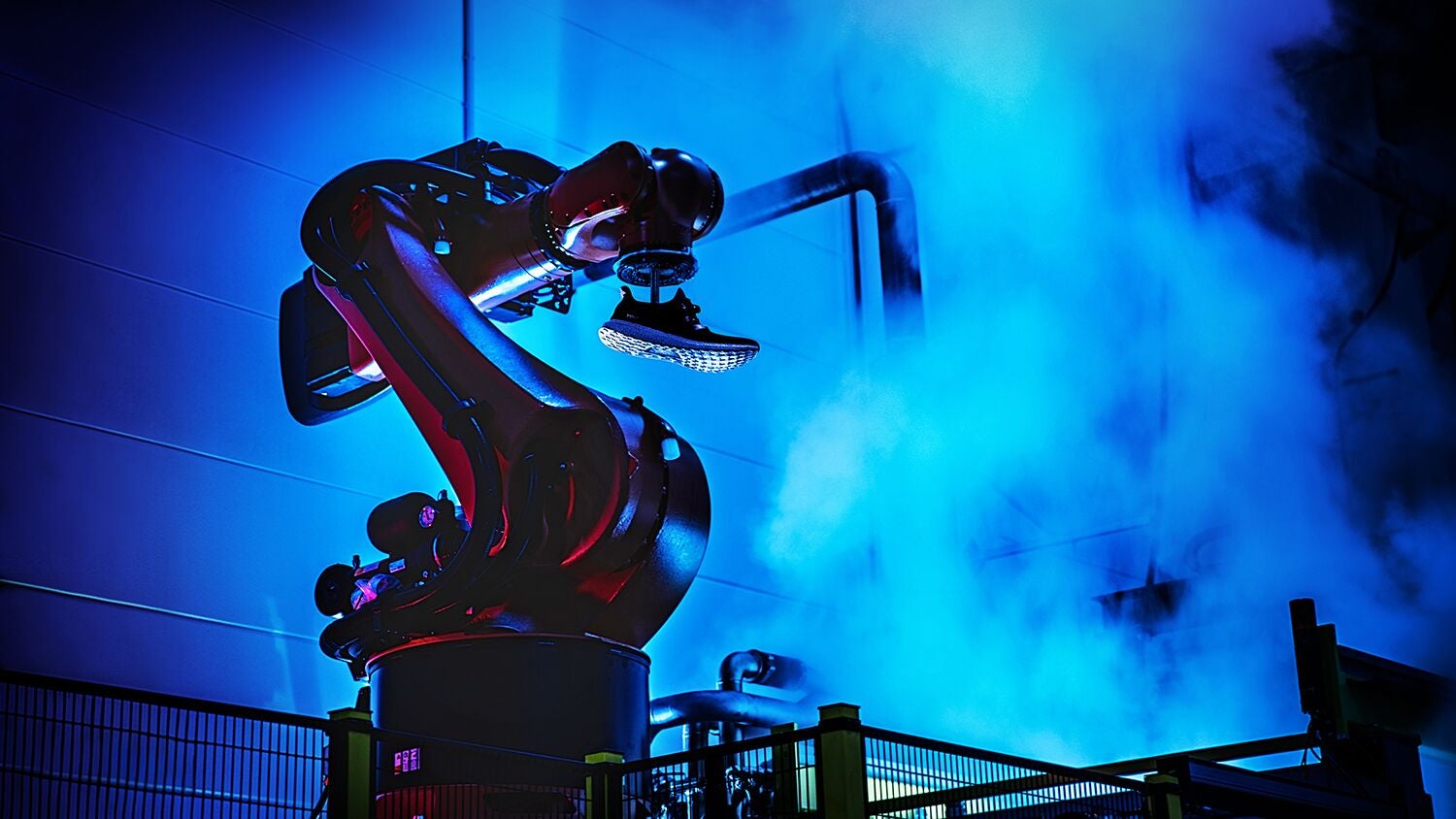

Adidas has been investing in automation as part of its greater push to speed up its supply chain. At the end of 2015, it launched a high-tech Speedfactory in Germany that relies ”intelligent, robotic technology” to make sneakers more quickly. More recently, it unveiled a 3D-printed sneaker that knocks out a costly, time-consuming step from the manufacturing process.

But Rorsted was candid about how long he sees it taking before a robot could make a pair of sneakers from start to finish, saying he doesn’t predict full automation being possible in the “next five to 10 years.” And for now Adidas’ automated manufacturing will only produce about 1 million pairs of sneakers a year, a sliver of the 360 million pairs it produced in 2016, according to its most recent annual report (pdf).

Adidas’ German Speedfactory and a subsequent one in Atlanta have also put Adidas in the conversation about reshoring manufacturing to Europe and the US that has arisen with events such as Brexit and the election of Donald Trump. But Rorsted made clear that he doesn’t see reshoring occurring on any major scale.

“I do not believe, and it’s a complete illusion to believe, that manufacturing can go back to Europe in terms of volume,” he said. He added that there is a political interest in reshoring manufacturing to the US, but financially it is “very illogical” and unlikely to happen. “And that goes for the entire industry, I’m not speaking just for Adidas,” he said. (Increased duties on products made overseas aren’t likely to bring sneaker manufacturing back to the US either.)

While Adidas’ plants in Germany and the US focus on producing a relatively small number of sneakers for those important markets, the bulk of manufacturing will remain in Asia, which accounts for 97% of Adidas’ production.

In fact, Rorsted predicted that the sophisticated technologies developed to serve markets such as Europe and the US will ultimately be shipped back to China, where a massive manufacturing infrastructure—not to mention a growing and eager customer base—already awaits.