Coronavirus: All vialed up

Hello Quartz readers,

Hello Quartz readers,

Just over three months ago, we launched this newsletter to bring you a cool, calm, and collected look at a pandemic’s impacts on the global economy. Now, with lockdowns winding down, second waves winding up, and the scope of those impacts becoming clear, we want to hear how it’s going. What are you itching to learn more about? What’s the next big question on your mind? Should we add more puns?

And while we’re in your inbox, don’t forget to share Need to Know with a friend, family member, colleague, former nemesis, future collaborator, and that one guy on Facebook. They can also sign up here.

Let’s get started.

Glass act

On June 10, the US government’s Biomedical Advanced Research and Development Authority (BARDA) awarded a New York-based company $204 million in the race to distribute a Covid-19 vaccine. That company? Corning, which makes the glass vials needed to bottle and store vaccines.

Preparations can’t start soon enough: Glass production is already stretching to support clinical trials and research, and in a 60-page whistleblowing complaint about the government’s pandemic response, former BARDA chief Rick Bright warned of a looming shortage.

It might seem surprising that glass could be a significant bottleneck for vaccine distribution. But the type of glass needed to transport vaccines safely makes up just 10% of all the glass that companies produce. It’s more expensive, and requires specialized equipment to manufacture.

The majority of all glass is silicon dioxide—one part silicon, two parts oxygen. (Crystallized silicon dioxide is quartz, our namesake mineral.) Added chemicals can change the glass’s characteristics. Pharmaceutical glassware, part of a class called borosilicate glass, has higher levels of aluminum and boron, which decrease the glass’s reactivity, making it safe to transport drugs.

The issue with borosilicate glass, sometimes, is that at high temperatures, some of the boron can dislodge from the glass and resettle somewhere else in the vial, eventually creating microscopic glass particles that flake off. The product inside gets contaminated again. Corning’s pharmaceutical glass, called Valor Glass, “was intentionally designed to have optimized properties—without boron,” says Robert Schaut, the scientific director for Corning Pharmaceutical Technologies. It took years of tinkering to find a chemical composition that allowed essentially no reactivity at any temperature.

Borosilicate glass could work to hold new vaccines and drugs, but Valor Glass is an improved version. Both require more technical equipment and know-how than run of the mill soda-lime glass, which is used in our kitchenware and windows. That’s why Bright and others have been worried about shortages. The hope is that, with $204 million in funding, Corning will be able to support the pharmaceutical companies that BARDA has partnered with, although which vaccine its vials will be holding remains unclear.

And that’s just development and transportation. Once there’s a vaccine and enough vials to store it in, doctors will need the supplies to administer millions of shots. Last week, BARDA awarded $143 million to Alabama-based SiO2 Materials Science, to expand its production of syringes.

A shot in the arm

Here’s a pop quiz: How much does vaccine manufacturing and production typically cost?

a. $50 million

b. $100 million

c. $500 million

d. $1 billion

We won’t make you turn your laptop upside down—it’s C. And even under normal circumstances, market incentives are rarely strong enough to encourage taking on those costs. So public funding must come to the rescue: As of June, the US government has invested more than $2 billion in various companies’ coronavirus vaccine trials.

The scale of public funding for SARS-CoV-2 is “unprecedented”, says Tahir Amin, co-founder of I-MAK, a nonprofit focused on lowering drug prices. It’s also upending how companies evaluate risk and pursue research.

In this week’s field guide (✦ Quartz member exclusive), we’re looking at science’s great pandemic pivot: how an entire field is redeploying its research and advancing its work at a pace never seen before. You can read the full guide by redeploying $60 into a Quartz membership—that’s a 40% discount on your first year—or signing up for a seven-day free trial. Membership gives you unlimited access to our stories, presentations, field guides, and workshops. Consider it an inoculation against ignorance.

All is as it memes

Taiwan, lauded for its success in containing (✦) the spread of coronavirus, is using humor as a tool to fight the pandemic. Every time a hoax surfaces on social media, Taiwan’s digital minister, Audrey Tang, and a band of civic hackers respond with a joke containing the facts.

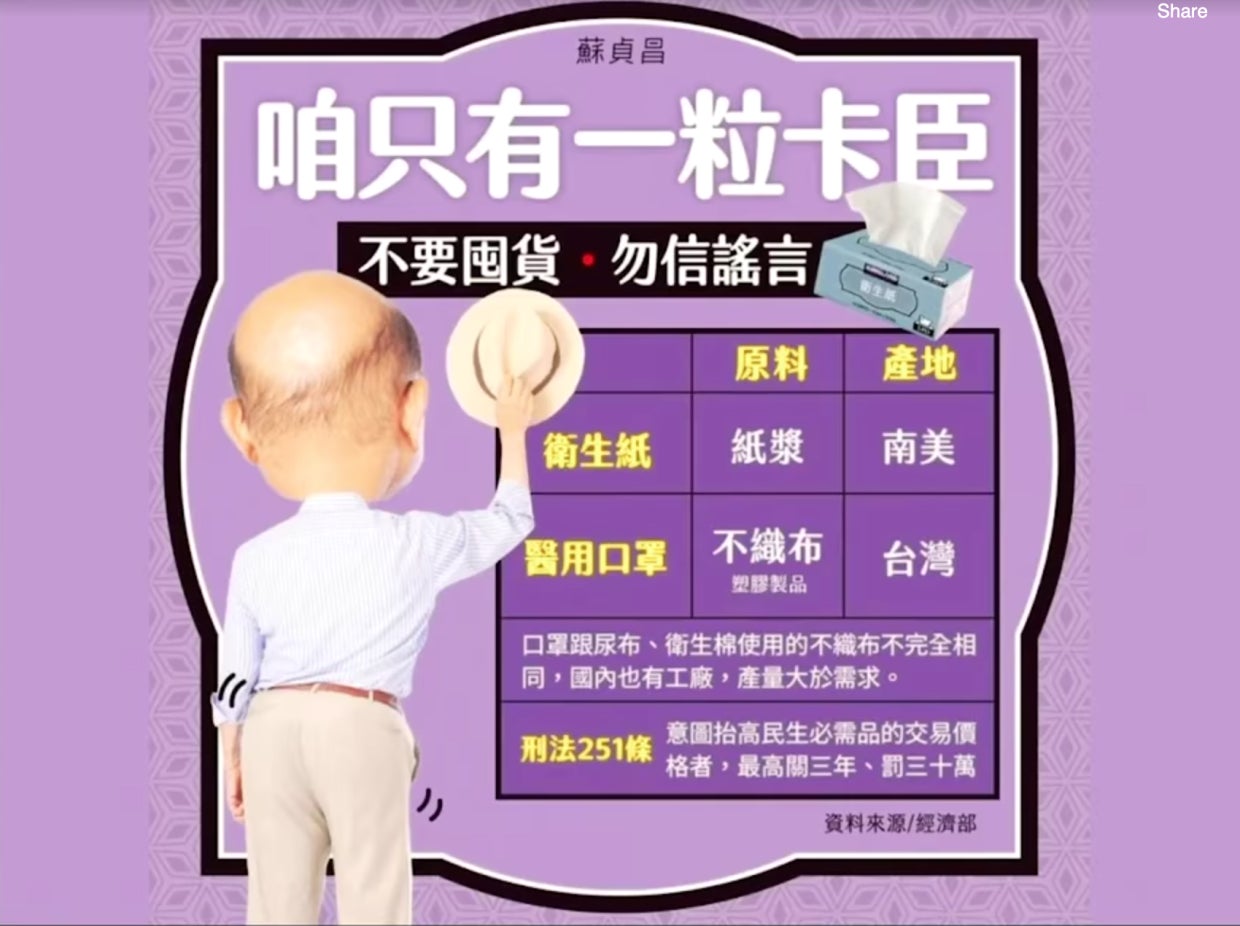

In one example, the Taiwanese government quelled panic–buying of toilet paper after rumors circulated online that increased production of face masks would compete with production of TP. In response, Tang’s team released a meme featuring Taiwan’s premier, Su Tseng-chang, sashaying his rear end, with the caption “we only have one pair of buttocks.” The graphic shows a table clarifying that the pulp in toilet paper is imported from South America and has no bearing on medical-mask production because those raw materials are sourced locally.

Hitting the right tone is critical. Explained Tang at a recent TED conference, “Humor is a sublimation of outrage.”

Call to ‘Action!’

As TV and film production starts to resume in Hollywood, the industry’s labor unions and the Alliance of Motion Picture and Television Producers joined forces to release a white paper (pdf) that includes recommendations for how to film safely. Here’s what some of the suggested protocols could mean for the industry:

- Fewer sex and fight scenes. “When maintaining physical distancing is not possible,” the white paper reads, “contact must be kept to the shortest amount of time possible.”

- The return of the laugh track. Filming in front of a live studio audience is “discouraged.”

- Electronic scripts. The use of paper should be minimized “whenever possible.”

- Longer shoots. The task force called for shorter work days and fewer consecutive work days.

- DIY hair & makeup. Some costume-design, makeup, and hairstyling work simply “may not be possible while maintaining physical distancing from others.”

The vandemic

If you live in the US, you might be seeing a lot more recreational vehicles (RVs) this summer.

In March, when the pandemic shut down the US economy, the values of Thor and Winnebago, the two biggest publicly traded RV companies, cratered even faster than the S&P 500. But their stock prices have steadily risen since, and soared in late May. Of the 31 publicly traded automobile manufactures worth at least $5 billion, Thor’s stock has performed third best since the beginning of February, trailing only Audi and Tesla.

Though numbers for May RV sales and shipments are not yet available, a survey conducted by market research firm Ipsos projects that 46 million Americans plan to take an RV trip within the next 12 months, compared with 25 million who said the same last year.

Essential reading

- The latest 🌏 figures: 8,092,109 confirmed cases; 3,918,176 classified as “recovered.”

- Hydroxychloroquitting: The FDA pulled its emergency-use authorization for the drug.

- Clusterf@#*: The largest US clusters are in prisons and meat-processing facilities.

- Remote possibility: 45% of US employers have yet to announce a return-to-work date.

- Coolcoolcool: A new study shows 1 in 5 people is at risk for a severe Covid-19 case.

Our best wishes for a healthy day. Get in touch with us at [email protected], and live your best Quartz life by downloading our app and becoming a member. Today’s newsletter was brought to you by Katherine Foley, Anne Quito, Adam Epstein, Alex Ossola, Dan Kopf, and Kira Bindrim.