European countries scrambling to heat homes and feed industry this winter have come up with a relatively quick fix: floating natural gas terminals.

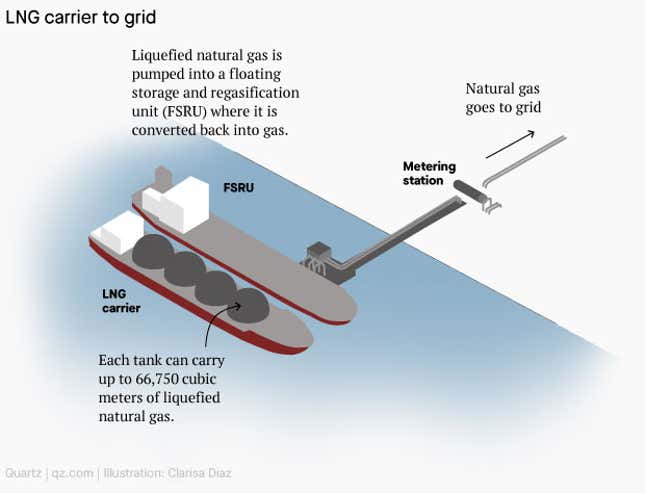

Liquid natural gas (LNG) carriers can bring in fuel from any exporter in the world, but they normally deliver their cargo through onshore terminals that can take years to build. Instead, several European countries, including the Netherlands and Germany, are resorting to floating storage regasification units (FSRUs)—essentially ships that can do the same job.

Suppliers of FSRUs are seeing a surge in demand. European countries have leased at least 25 FSRUs since Vladimir Putin’s invasion of Ukraine, with more anticipated to come as the region struggles to replace Russian gas.

Exmar, which makes and installs FSRUs, normally handles only one to three projects per year. “Now we have seen a rush with about ten FSRUs being chartered in a period of less than six months,” said Jonathan Raes, a director of infrastructure at the Belgium-based company.

Here’s an overview of how the system works:

What is a temporary solution, however, may become longer term. The average lease length of an FSRU is 10 to 12 years. “Typically once on-site and in operation the tendency is to have them longer,” said Raes. An FSRU has a lifespan of about 20 years.

A quick fix, but is it sustainable?

It usually takes 12 to 18 months to install a new FSRU, but given the EU’s sense of urgency, Raes estimates some projects are being launched in half that time. “If and where possible, terminal developers look to re-use as much available and existing infrastructure,” he said. “This reduces cost and compresses the timeline.”

FSRUs are more cost-effective and faster to build than onshore terminals, which can take up to seven years to be completed and can cost more than $700 million. A new FSRU costs about $260 million, whereas one that has been refurbished from an LNG carrier goes for around $160 million.

But FSRUs hold much less fuel, with a peak capacity of around 4 million tons annually compared to around 7.75 million tons with onshore terminals.

“FSRUs are definitely already more sustainable than onshore terminals because of their smaller environmental footprint,” said Raes. But LNG itself is more carbon-intensive than piped gas.

To help Europe get off fossil fuels FSRUs would need to be replaced or retrofitted. For example, in the future, they could be used to import synthetic methane, a green alternative to natural gas made with hydrogen that is still being developed.