Engineers need better tools to design spacecraft and robots more quickly

Dear readers,

Dear readers,

Welcome to Quartz’s newsletter on the economic possibilities of the extraterrestrial sphere. Please forward widely, and let me know what you think. This week: Github for hardware, that space telescope you might have heard about, and the one year anniversary of Richard Branson’s trip to space.

🚀 🚀 🚀

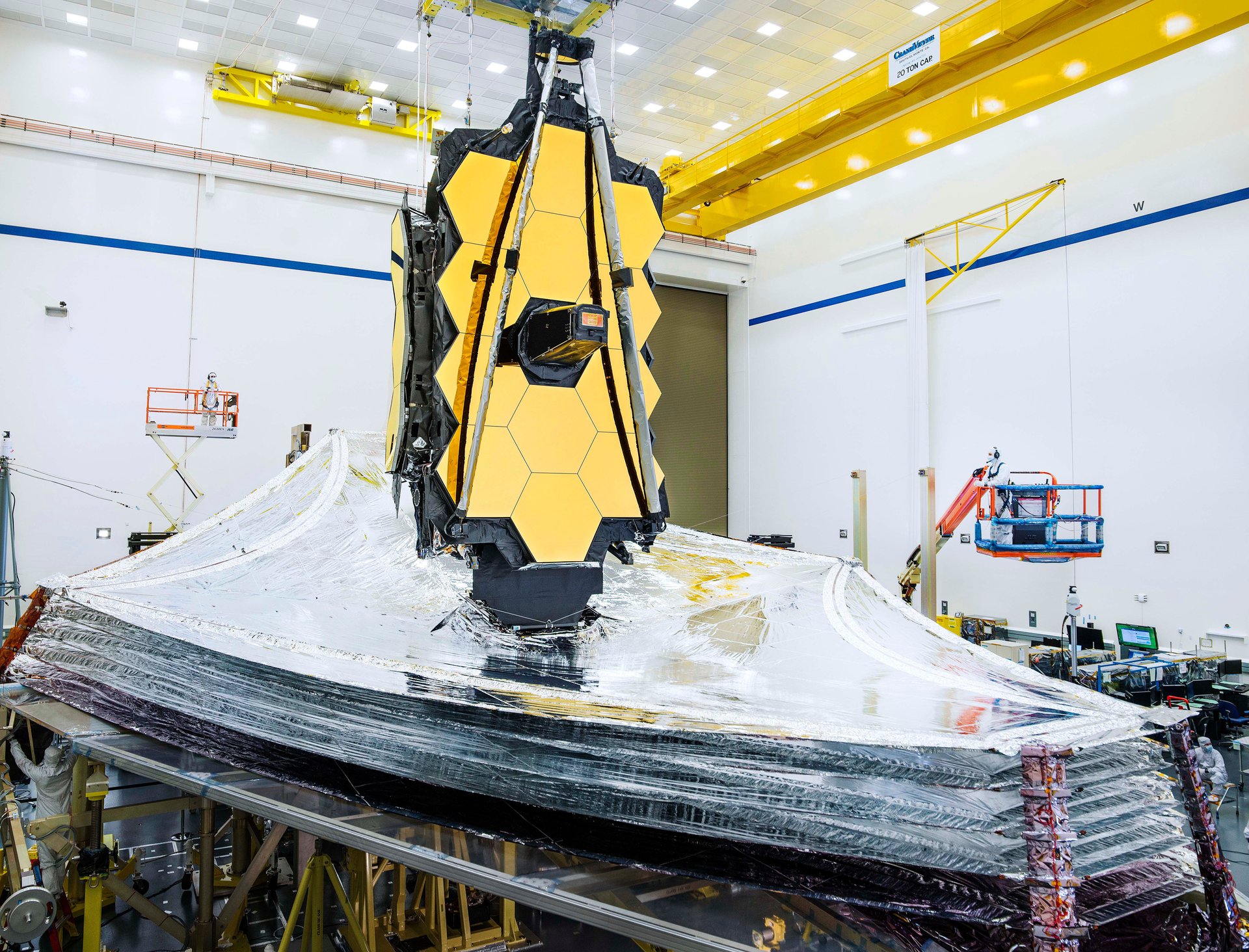

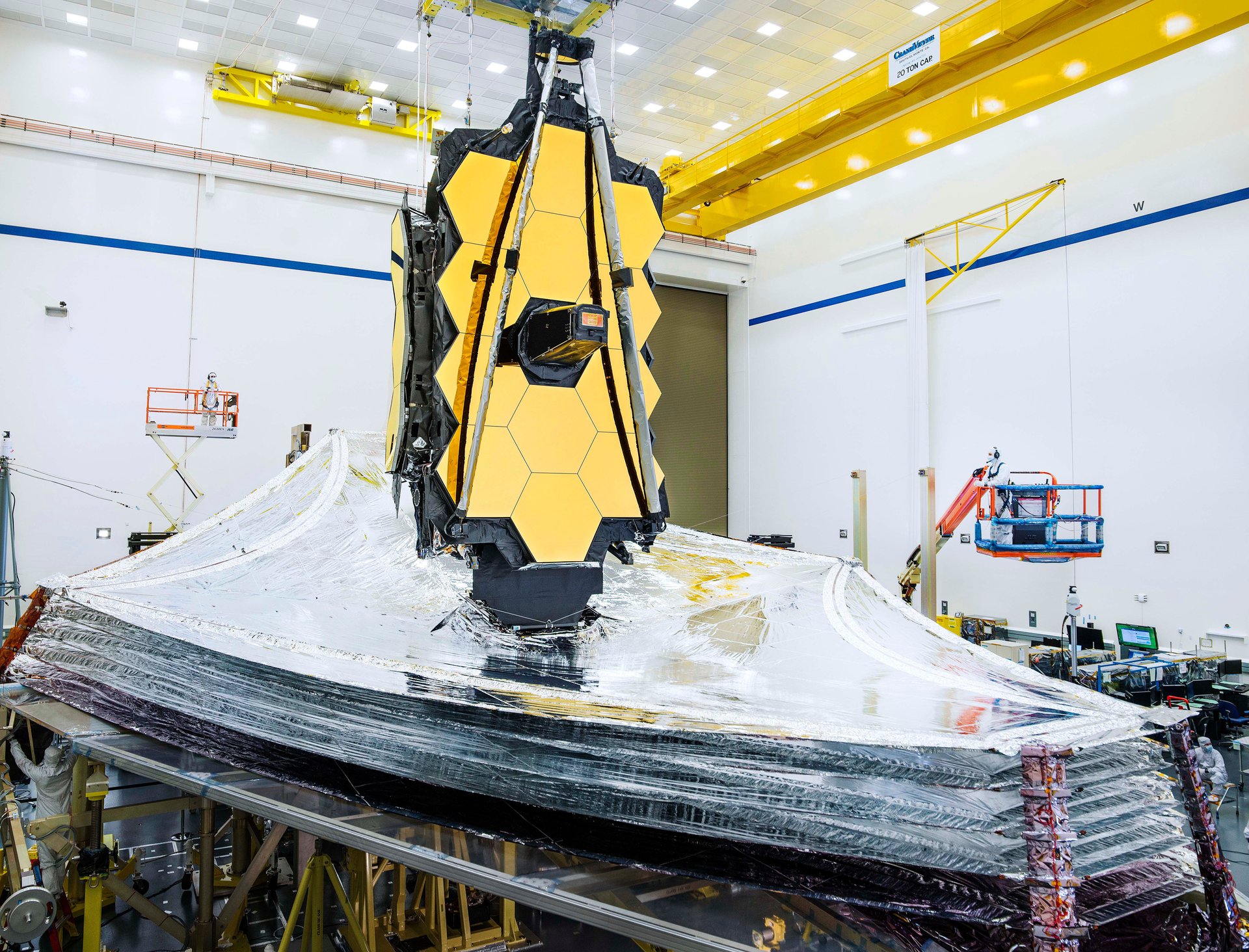

One reason we didn’t see this week’s astonishing images from the James Webb Telescope sooner? In a 2018 vibration test to anticipate the rigors of space launch, screws popped out of the spacecraft. The cause was a missing specification for how tight the screws should be—and they weren’t tight enough.

Building anything, much less a $10 billion bespoke piece of frontier sensing technology, is a complicated job. Engineers rely on computer-aided design tools to turn their ideas into specifications that can be replicated in reality, to simulate their behavior, track key data, and convey all that information to the people who build that thing.

Engineers and companies that build hardware like spacecraft, airplanes, and cars are increasingly finding that the tools they have now are insufficient to do those jobs, especially compared to the wealth of new tools used by software engineers. Cloud-computing, APIs, and platforms like GitHub let coders automate workflows, share modular designs, and update coworkers about changes in real-time.

“The only way to interact with your hardware design is with a mouse, there’s no way to do it through code,” explains Jordan Noone, a co-founder of the rocket maker Relativity Space, who is now partner at the fund Embedded Ventures. Noone is also CEO of a new company Embedded is backing called KittyCAD which aims to change that.

KittyCAD isn’t aiming to replace common CAD software made by companies like SolidWorks, Autodesk or Creo—at least, not yet. Today, they’re announcing the rollout of an API designed to make these programs more easily automated and interoperable with each other, and with project management software.

For example, Noone describes an engineer designing a custom bolt for a piece of hardware by hand, consulting specification manuals and rendering it click-by-click. In a KittyCAD world, the parameters of that bolt could be defined in code, the design generated automatically, rendered in 2D and 3D with metadata about tolerances and manufacturing included, pushed into project management software and turned into a product order.

Noone and his co-founders, Embedded partner Jenna Bryant, chief scientist Jessie Frazelle, and CTO Hannah Bollar, posted a note about the project on GitHub last year. They let me review a slew of email replies from frustrated engineers describing their jerry-rigged automation attempts and asking for consistent solutions to these problems. Many had experience in software engineering as well and were familiar with the gulf between the two disciplines.

Lucy Hoag is one of those people. Trained as an astronautical engineer, she’s worked on spacecraft for DARPA, Google, and Amazon, and led a team of engineers developing self-driving cars at Lyft. Her new company, Violet Labs, also aims to create new tools for hardware engineers. She envisions it running on the APIs built by KittyCAD.

It’s easy to see how this could enhance productivity. In a satellite design project, the engineers designing the guidance, navigation and control systems need to obtain key information, like the spacecraft’s mass and center of gravity, from the team designing its structure. At a previous employer, Hoag told me that information exchange was essentially done by hand, over email. It took about a month to get the parameters nailed down, but in her view it’s an exercise that should take a week.

This may seem like the basic procedural problems that engineers should have solved. But as with JWST, big projects can be derailed by small problems. Boeing’s troubled Starliner space capsule, for example, missed a problem with the propulsion control software because configuration data didn’t match the actual valves and thrusters used by the capsule. To avoid losing the spacecraft during its first flight test, engineers had to re-test the software on the ground and patch it in-flight. Boeing, which lost nearly $600 million due to this and other failures, later conceded that it should have caught the problem.

SpaceX, on the other hand, went through its own software revolution after a rocket carrying cargo to the International Space Station exploded. In less than two years, it had developed a suite of tools that tracked design drawings and notes throughout the manufacturing process and automatically pushed design changes throughout the system. It could even spot data entry errors and bad test outcomes. One NASA staffer briefed on these tools said he wished NASA had systems like that to design the space shuttle.

“I think it’s no surprise that SpaceX, as a 10,000 person company, has developed some level of automation,” Noone says. “What KittyCAD is offering is a toolkit that anyone can use and adopt, at any scale of company, without having to develop any of it themselves, in addition to allowing developers and startups to create tools for others to use.”

There is a lot of talk in the venture capital world about the need to build more stuff in the physical realm. If we want robotics, transportation and energy products to evolve at the rate of software companies, the tools will have to catch up, too.

✨✨✨

Imagery interlude

I mean, what were you expecting?

I’m confident my readers have spent some time poring over these images already, but that’s no reason to stop.

Here are some of my favorite Webb stories, in case you missed them:

- Natalie Wolchover won a Pulitzer Prize for this 2021 deep dive into the history, science and humans behind this telescope; I can’t recommend it enough.

- I’m personally furious at Joshua Sokol for getting an incredible behind-the-scenes look at how these first pictures were chosen and created.

- One of the nicer duties of journalism is witnessing people bask in amazing accomplishments. Check out Ken Chang’s profile of Greg Robinson, the project leader who kept the Webb on course.

- Webb’s data link is 25 times faster than Hubble’s, but will still have to share the line with its Deep Space Network siblings.

- We sent a robot instead of a poet, but Barry Petchesky captured my mood about the ancient light we witnessed.

🛰🛰🛰

SPACE DEBRIS

Whither Virgin Galactic? A year after Richard Branson beat Jeff Bezos to space, the former’s space tourism company looks lost in the wilderness. A lack of regular flights and open technical questions have put the company’s financial future in question, even as the broader space tourism industry looks to catch on.

Death from Above. Researchers have calculated that there is a 10% chance of someone being hurt by falling rocket parts in the next decade thanks to the steady increase in launches and the still common practice of discarding spent rocket bodies in the atmosphere. Chinese boosters are a main culprit, but even SpaceX dropped a tank onto a farm in Washington state.

Whoops. SpaceX’s enormous Starship booster rocket encountered some kind of anomaly during testing this week—and kaboom. Elon Musk says the vehicle needs to return to its hangar for analysis, which likely means another delay for the rocket’s much-anticipated orbital test flight.

My test is better. OneWeb, the satellite internet operator, has submitted its own study to the Federal Communications Committee arguing that 5G networks planned by Dish, the satellite TV company, will cause interference problems. The fight over the 12 GHz spectrum band is heating up after OneWeb and SpaceX reversed their traditional enmity to join forces and oppose Dish’s plan.

It’s Vega, baby. Europe’s leading rocket maker, Arianespace, debuted the first Vega C rocket in a launch from French Guiana on July 13. The updated design will loft larger satellites, helping replace the Soyuz rocket that Europe can no longer access due to sanctions on Russia following its invasion of Ukraine.

Your pal,

Tim

This was issue 142 of our newsletter. Hope your week is out of this world! Please send your dreams for the next big space telescope, predictions for the space tourism market, tips, and informed opinions to [email protected].