Hi Quartz members!

Before the pandemic, shipping was experiencing a lost decade of low profits and idled fleets. Then the orders started coming in. Lawn mowers and sofas, milk frothers and exercycles—the shopping whims of a US under lockdown, tapping the buy now button at such stunning speeds that it broke the supply chain.

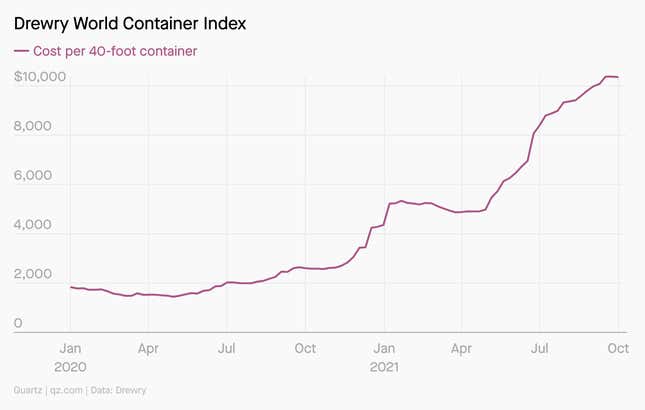

Massive ships loaded to the hilt at Chinese ports steamed across the Pacific, where longshore workers couldn’t pull the containers off fast enough. Those containers piled up at railheads, and their contents packed distribution centers without enough truck drivers to transport them. Each new shipload compounded the congestion, and the price to ship a container skyrocketed. With goods piling up at docks, the numbers of ships waiting to berth rose to a dozen, then to more than 60.

Frantic to meet America’s ravenous demand, some companies are now turning to expensive air freight. Others are chartering their own ships, or paying premium rates to muscle their goods onto one. Meanwhile, the pandemic shopping spree is charging straight into a holiday buying season, and the one thing that could reduce shipping strain—American shoppers buying less stuff—seems increasingly unlikely. Buy less? In this economy?

The system is now backed up enough that, by some estimates, this could go on until the end of 2022. What’s worse, because all links of the supply change are stuck in triage, everything that we’re now painfully aware needs to be fixed—shipping, ports, rails, trucking, warehousing, roads—lacks the downtime for said repairs, let alone for major rethinking. After all, that kind of overhaul would take years.

We’ve been down this road before, of letting systemic problems fester until they turn into full-blown crises (see: Covid, climate change). For now, people and companies are scrambling to make do. The next year will make clear how much we’ve learned.

The backstory

- Pre-pandemic, shipping profits were razor thin. The supply of space onboard container ships exceeded the demand, so few shipping lines were building up capacity. When the pandemic struck, many lines mothballed their ships, expecting a drop in demand.

- Now demand is off the charts. Retailers are desperate to restock depleted inventories as the holiday shopping season approaches, and with more market power than they’ve had in years, shipping lines are raising rates, ditching long-time customers in favor of higher bidders, running up fees and penalties at ports, and passing the costs onto their clients.

- It’s too late for some solutions. It can take two or three years to build a container ship, so new orders from shipping companies won’t help things now. Upgrading port infrastructure could take longer still—even if US lawmakers could muscle an infrastructure funding package through Congress.

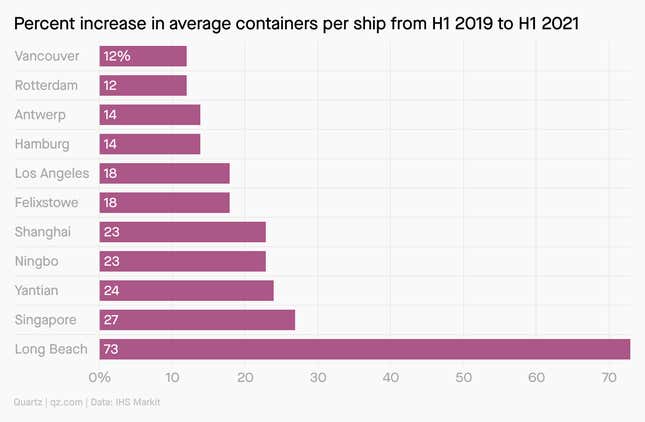

That’s heavy

Cargo ships are piled higher with containers than they’ve ever been. At California’s Port of Long Beach, which has been mired in record backlogs, the average ship now brings in 7,000 containers—up 70% from the pre-pandemic average of 4,000.

The problem is infrastructure: Every berth at a port has a fixed number of cranes, which means ports can’t ramp up capacity just because ships are carrying more. Similarly, shipyards have limited space. The more containers, the greater the logistical challenge of stacking, unstacking, and restacking them.

What to watch for next

- The quest for viable alternatives. Companies are searching for any option that isn’t standard container shipping on major carriers. Some have turned to air freight, which is even more expensive, but at least delivers goods quickly and more reliably.

- Desperate retailers going big. Some companies—including Costco, Walmart, Home Depot, IKEA, Dollar Tree, and Party City—have chartered their own cargo ships to circumvent shipping lines entirely. Others are securing space on ships by locking themselves into expensive, long-term contracts.

- A container price correction. To placate customers, a few shipping lines are freezing spot rates, albeit at high levels. As a Global Shippers’ Forum director put it: “It’s like the torturer asking the prisoner, ‘Aren’t you grateful I’m not turning the screw on the rack any further?'”

- The holiday shopping season. Supply chain disruptions threaten to create delays, stockouts, higher prices, and fewer discounts during the frantic quarter when many retailers make the bulk of their sales.

- What shipping lines do with their pandemic profits. With billions of dollars in the bank, they may choose to acquire rivals or related businesses, diversify into new industries like air freight and logistics, or simply build up a cash reserve in preparation for their eventual return to the old days of low profits and high volatility.

It’s the climb

The cost of a 40-foot container did decline a modest 0.2% this week, to $10,360. But the rate is still triple what it was a year ago.

One 🕴️ thing

One person watching the supply chain crises unfold is Japan’s new minister of economic security, the country’s first—and the first ministerial economic security role in the world. Takayuki Kobayashi, a three-term lawmaker who goes by “Kobahawk” on Twitter (taka means hawk in Japanese), is tasked with shoring up Japan’s supply chains, securing critical infrastructure, protecting technological advantages, and countering economic espionage. No pressure!

Quartz stories to spark conversation

🇨🇳 Biden’s new China trade policy looks a lot like Trump’s

🗳️ India is testing online voting based on the blockchain

🤠 Why Tesla is officially moving to Texas

🚗 The activist fund that shook Exxon is now investing in GM

💱 What is the point of a stablecoin?

🔮 Facebook is shutting down one of its most interesting experiments

🤖 Amazon’s Astro robot has at least one obvious purpose

🎙️ The Quartz Obsession podcast starts in three days!

5 great stories from elsewhere

🎮 Inside the PS5 feeding frenzy. BuzzFeed News profiles tech journalist Matt Swider, whose tips on acquiring a coveted PlayStation 5 turned him into a pandemic celebrity.

🚢 One decaying supertanker to watch. The New Yorker takes a harrowing look at a ship stranded in Yemen that could spill a million barrels of crude at any moment.

🧠 Why Facebook went down. Engineers at internet security company Cloudflare explain (with diagrams!) how the social network briefly disappeared from the internet.

💞 The arc of true love is long. The Washington Post tells the story of an interracial romance that ended in 1979, only to be beautifully rekindled 42 years later.

💡 Rewilding your attention online. UX Collective pushes the power of seeking out weird, eclectic, and niche content—not served up by algorithms—to cultivate new ideas.

Thanks for reading! And don’t hesitate to reach out with comments, questions, or topics you want to know more about.

Best wishes for a contained weekend,

Aurora Almendral, senior reporter (spent 10 days on a cargo ship)

Nicolás Rivero, reporter (spent middle school in cargo shorts)

Kira Bindrim, executive editor (spent too much on a milk frother)